Hex Socket Cap Screw – Durable, Precise Fasteners for Global Industry

Hex Socket Cap Screw: The Unsung Hero of Modern Assembly

At first glance, a hex socket cap screw might seem like just another piece of metal, but its significance is quite global, touching everything from giant industrial machines to the tiniest gadgets in your pocket. Across industries and continents, these fasteners hold machines, structures, and devices together reliably. Understanding what makes them so indispensable—durability, compact design, and ease of use—provides insight into why engineers and manufacturers swear by them worldwide. So let’s unpack the nuts and bolts of these small but mighty components.

Why Hex Socket Cap Screws Matter Globally

In a world increasingly reliant on machinery, transportation, and infrastructure, hex socket cap screws serve as the backbone of safe, efficient assembly. According to ISO standards, reliable fastening solutions reduce industrial accidents and boost machinery lifespan by up to 30% when properly specified (ISO 898-1). Globally, billions of these screws are used annually in sectors ranging from aerospace to renewable energy. Oddly enough, despite their prevalence, many manufacturers still underestimate their critical role, which can lead to costly maintenance or failure.

One challenge that often arises in manufacturing is achieving high torque with limited space; that’s where the hex socket cap screw shines. Its internal hexagon drive allows for compact, high-torque fastening without stripping or damage, making it ideal for precision and heavy-duty usage. In disaster relief equipment, for example, where speed and reliability under stress can save lives, choosing the correct fastener is vital.

What Exactly Is a Hex Socket Cap Screw?

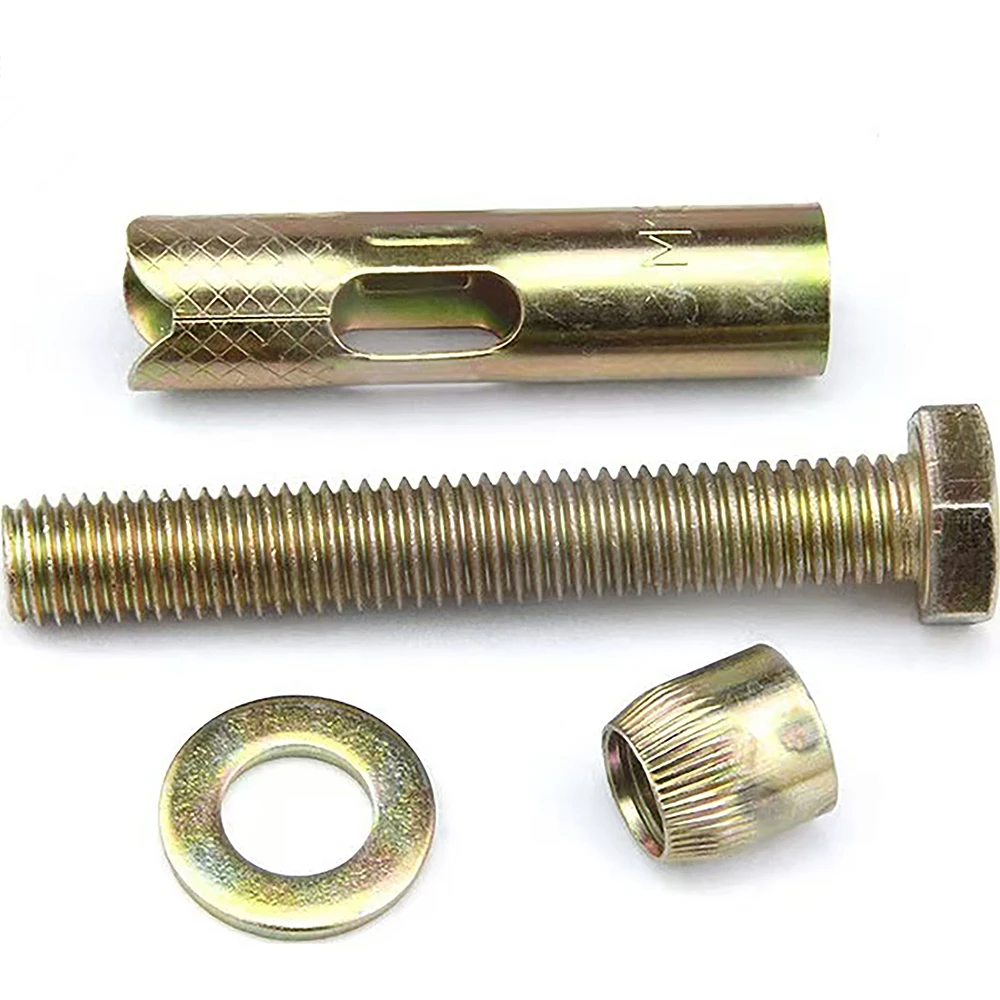

Simply put, a hex socket cap screw is a type of fastener characterized by a cylindrical head with a recessed hexagonal drive. Instead of a traditional slotted or Phillips head, it relies on an Allen wrench or hex key, allowing insertion into tighter spaces with better torque control. This design makes it uniquely suited for assembly tasks where surface clearance is limited or a strong clamping force is needed.

They’re part of the family of socket screws but are distinguished by their tall cylindrical heads, often used in mechanical and structural applications. Their role is not just technical; they support critical infrastructure, from humanitarian aid logistics to everyday vehicles, blending seamlessly into the fabric of modern industry.

Mini takeaway:

Think of hex socket cap screws as stealth connectors — small, strong, yet indispensable, making big things work quietly.

Core Components of Hex Socket Cap Screws

1. Durability

Most hex socket cap screws are made from high-grade alloy steel, stainless steel, or titanium, offering excellent resistance to corrosion, wear, and deformation — a must for long-term reliability. Stainless variants suit marine or outdoor use, while alloy steels balance strength and cost.

2. Precision Manufacturing

Manufacturing tolerances are tight, so these screws maintain consistent fits, preventing loosening in high-vibration contexts such as automotive engines or aircraft structures. This precision protects against “vibration loosening,” a common cause of mechanical failure.

3. Compact Drive Design

The hexagonal socket inside the head provides more surface contact for tools than Phillips or slotted heads, minimizing cam-out (tool slippage) and improving torque transfer. It’s fascinating how this small change drives big improvements in manufacturing efficiency.

4. Versatility

They come in various lengths, diameters, thread types, and materials — making them adaptable across industries from electronics manufacturing to construction scaffolding.

5. Cost Efficiency

Though slightly more expensive than conventional screws, their longevity and reduced maintenance costs often outweigh the upfront investment.

| Specification | Typical Values | Notes |

|---|---|---|

| Material | Alloy Steel / Stainless Steel / Titanium | Varies by application environment |

| Head Diameter | 5mm to 30mm | Depends on screw size |

| Thread Pitch | Coarse (standard) or Fine thread | For different load requirements |

| Drive Type | Internal hexagon (Allen key compatible) | Ensures high torque and slip resistance |

| Tensile Strength | Up to 1200 MPa | High strength for demanding uses |

Mini takeaway:

The engineering behind these screws balances durability, precision, and cost — a triple win for designers and end users.

Where Hex Socket Cap Screws Make a Difference Worldwide

It’s pretty remarkable how these small screws pop up everywhere: from Japanese robotics labs to massive European wind turbines to mobile clinics in Sub-Saharan Africa. Industries that demand resilient and compact fastening solutions embrace them— automotive manufacturers in Germany, aerospace firms in the US, and electronics factories in South Korea.

- Post-disaster relief: Modular shelters use them for fast assembly and disassembly, lending mechanical strength while keeping tools simple.

- Remote industrial zones: Mining and oil rigs rely on stainless steel variants for resistance to corrosion and vibration.

- Renewable energy: Solar panel mounts and wind turbine assemblies depend on the reliability of hex socket screws to withstand environmental extremes.

Even humanitarian organizations like Red Cross prefer them in field kits for making sturdy temporary facilities quickly, proving their social impact extends beyond industry. In many ways, these fasteners are a quiet enabler of progress and safety.

Mini takeaway:

Across harsh deserts or cutting-edge factories, hex socket cap screws keep things fastened securely, quietly powering progress.

The Long-Term Value of Using Hex Socket Cap Screws

Their benefits extend beyond technical specs. From a practical standpoint: fewer maintenance calls, safer equipment, and less downtime. Emotionally, the feeling that your assembly won’t unexpectedly fail gives peace of mind — be it a child's stroller, a car engine, or a critical hospital device.

Cost-wise, while initial costs may be a bit higher, long-term savings come from less replacement, improved machine uptime, and compatibility with automation tools that speed mass assembly processes. Sustainability fits in here too: longer-lasting fasteners reduce waste and landfill load, aligning with ISO 14001 environmental goals.

Mini takeaway:

Hex socket cap screws deliver value in money saved, safety earned, and environmental legacy preserved.

Looking Forward: Trends and Innovations in the Fastening World

We’re on the brink of some genuinely cool advances in hex socket screw tech. For example, green coatings that reduce friction and corrosion while being eco-friendly are catching on. Additive manufacturing allows custom threads or strengths tailored perfectly to specific stress points, optimizing weight and performance.

Digitally, smart torque tools now communicate real-time data during assembly, ensuring no screw is under- or over-tightened — a game changer in aerospace and medical device manufacturing.

Automation integration means robots can handle these fasteners in tighter production cycles, minimizing human error. In short: the marriage of materials science and Industry 4.0 promises a future where quality control is near flawless.

Common Challenges and Practical Solutions

Of course, no product is without hiccups. For hex socket cap screws, one issue is tool compatibility — the demand for precise Allen keys means you have to keep the right sizes handy or risk rounding the socket. Also, corrosion remains a stubborn problem if the wrong material is chosen.

Experts suggest specifying material-grade carefully based on environment and using coated screws where humidity or chemicals are present. Another smart tip is employing thread-locking compounds or washers designed to minimize loosening without hindering maintenance.

FAQ: Frequently Asked Questions About Hex Socket Cap Screws

- What advantages do hex socket cap screws offer compared to traditional bolts?

- Hex socket cap screws allow higher torque in narrow spaces thanks to their internal hex drive, reducing tool slippage and enabling compact designs. They’re also often stronger and provide cleaner aesthetics in assemblies.

- Are these screws suitable for outdoor applications?

- Yes, provided you choose corrosion-resistant materials like stainless steel or apply protective coatings. Many outdoor structures and machinery use coated hex socket cap screws to withstand wind, rain, and temperature swings.

- Can I use an ordinary screwdriver to remove hex socket cap screws?

- No. These screws require a hex key (Allen wrench) or compatible bit. Using inappropriate tools risks damaging the socket, making removal difficult or impossible without special extraction tools.

- How do I know what size hex key to use?

- Most manufacturers provide a size chart linking screw diameter to hex key size. It’s best to use a calibrated set of hex keys for precision and to avoid rounding the socket edges.

- Can these screws be recycled or reused?

- They can be recycled, especially metal variants (steel, titanium). Reuse depends on condition — if the socket or threads are undamaged, reuse is possible but inspect for corrosion or wear carefully.

Summing Up: Small Screws, Big Impact

In real terms, choosing the right hex socket cap screw can be the difference between an efficient, lasting assembly and costly failures. From factory floors to humanitarian missions, they punch well above their weight. If you’re looking to optimize your next project, consider how these precise, durable fasteners can improve functionality, reduce maintenance, and ensure safety.

For more detailed selections and expert advice, visit our website: https://www.fastenboen.com.

References:

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.