DIN933 Hex Bolts - High-Strength, Corrosion-Resistant

Din933 Hex Bolts is a key solution in the manufacturing industry, specifically within Metal products industry and Manufacturing of fasteners, springs, and other metal products. This article explores how Handan Boen Fastener Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Din933 Hex Bolts Overview

- Benefits & Use Cases of Din933 Hex Bolts in Manufacturing of fasteners, springs, and other metal products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Din933 Hex Bolts from Handan Boen Fastener Manufacturing Co., Ltd.

Din933 Hex Bolts Overview

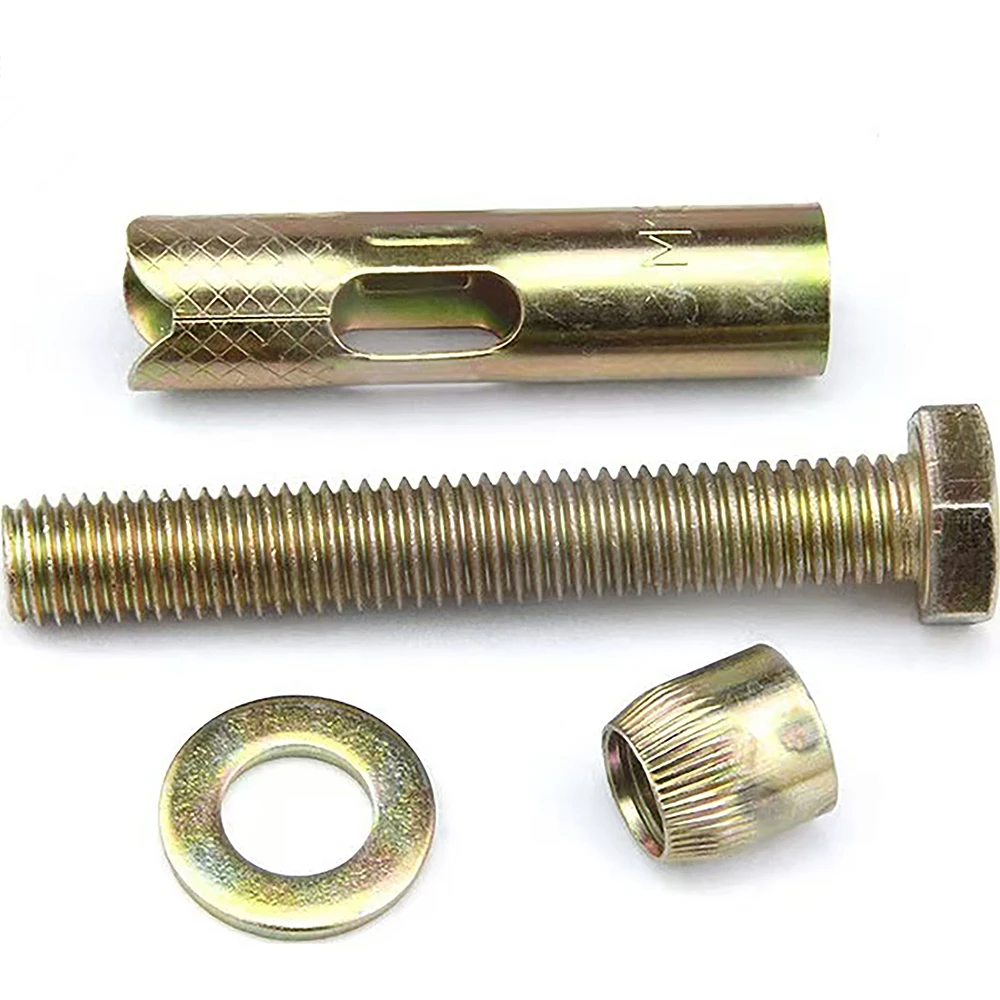

DIN 933 Hex Bolts are full-threaded hexagon head bolts designed for secure, high-strength assemblies across machinery, tooling, and structural applications. In the Metal products industry—especially the Manufacturing of fasteners, springs, and other metal products—these bolts deliver repeatable clamping force, easy wrench access, and compatibility with automated assembly lines. Compared with DIN 931 hex bolts (partial thread), DIN 933 is preferred where maximum grip length isn’t critical and vibration resistance or fine positional adjustment is needed along the full thread. Handan Boen Fastener Manufacturing Co., Ltd. manufactures Din933 Hex Bolts with consistent thread geometry and head-to-thread concentricity to minimize assembly variability.

- Typical specs: metric sizes M5–M48, coarse thread per DIN/ISO, property classes 4.8/8.8/10.9/12.9, materials from carbon steel to stainless (A2/A4), finishes including zinc plating, hot-dip galvanizing, Dacromet, and black oxide.

- Interchangeability: aligns with ISO 4017; pairs with ISO 4032 hex nuts and DIN 125/ISO 7089 washers. For partial-thread needs, DIN 931 hex bolts are the sister standard.

- Use example: a spring coiling machine build uses DIN 933 M10 class 8.8 for motor mounts to simplify changeovers, while critical frame joints use DIN 931 M10 where unthreaded shank improves shear performance.

- Handan Boen provides stable lead times, dimensional consistency, and documentation upon request to support OEM and MRO buyers.

Benefits & Use Cases of Din933 Hex Bolts in Manufacturing of fasteners, springs, and other metal products

In factories producing fasteners, springs, stampings, and assemblies, Din933 Hex Bolts are a staple for equipment frames, guards, conveyors, tool holders, coil pay-off stands, and packaging cells. Full-thread design enables flexible clamping of variable stack-ups, making it ideal for jigs/fixtures and continuous improvement projects. Where a non-threaded grip is needed, engineers often specify din931 hex bolts instead; for example, a din931 m10 in property class 8.8 is common for locating heavy plates without thread engagement at the shear plane, while Din933 provides total engagement across the joint.

- Applications: press bases, feeder systems, furnace enclosures, maintenance spares, and modular fixtures in spring winding and fastener cold-heading lines.

- Advantages: wide availability, wrench-friendly hex head, predictable torque-tension behavior, and coating options to match indoor/outdoor and corrosive environments.

- Material match: for many machine frames, class 8.8 offers a strong balance of cost and performance. When a partial-thread is required with equivalent strength, engineers turn to din 931 8.8 material to meet the same load class with an unthreaded shank.

- Handan Boen’s expertise spans cold-heading, precision threading, controlled heat treatment, and finishing—helping B2B buyers align specifications with real-world operating conditions.

Cost, Maintenance & User Experience

Total cost of ownership for Din933 Hex Bolts hinges on three levers: correct property class, appropriate coating, and supply stability. Selecting class 8.8 for general assemblies avoids over-specification, while 10.9/12.9 is reserved for high-stress joints. Coatings should reflect environment (zinc for indoor dry areas; HDG or stainless for corrosive exposure). Handan Boen helps B2B teams standardize SKUs around common sizes like M8–M16—reducing inventory complexity and assembly time.

- ROI perspective: fewer line stoppages from bolt stretch or corrosion translates into measurable savings. Standardization on Din933 Hex Bolts shortens changeovers and supports torque-controlled assembly.

- Maintenance tips: verify torque after first thermal cycle, re-lube threads when reusing, protect stock from humidity, and pair with matching nuts/washers from the same coating system to avoid galvanic issues.

- User feedback from metal product manufacturers highlights consistent fit, clean threads, and reliable packaging—factors that reduce scrap and rework in both OEM builds and MRO activities.

Sustainability & Market Trends in manufacturing

Sustainability is shaping fastener sourcing as buyers favor chromium VI–free passivation, recyclable packaging, and efficient heat-treatment processes. Regulatory frameworks such as RoHS and REACH guide material and finishing choices, while ISO/EN harmonization (e.g., ISO 4017) ensures global interchangeability for Din933 Hex Bolts. Supply-chain resilience remains a priority, prompting many B2B teams to dual-source and align with manufacturers that offer process transparency and traceability.

- Handan Boen Fastener Manufacturing Co., Ltd. emphasizes efficient production, waste reduction, and responsible finishing selections to help customers meet environmental targets without compromising performance.

- Market trend: consolidation around standard sizes and coatings, alongside digital documentation and quality data sharing, enables faster approvals and smoother audits for industrial buyers.

Conclusion on Din933 Hex Bolts from Handan Boen Fastener Manufacturing Co., Ltd.

For manufacturers of fasteners, springs, and metal products, Din933 Hex Bolts deliver proven strength, predictable torque-tension behavior, and broad compatibility with common nuts and washers. Where partial-thread is needed, DIN 931 remains a perfect complement—whether you spec a DIN 931 M10 in class 8.8 or other sizes. Handan Boen Fastener Manufacturing Co., Ltd. combines reliable production with practical application support to keep your lines running and your assemblies secure. Contact us: email: shaun@boenfasteners.com — Visit our website: https://www.fastenboen.com

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.