Sleeve Anchors – Heavy-Duty, Corrosion-Resistant

Masonry Sleeve Anchors is a key solution in the manufacturing industry, specifically within Metal products industry and Manufacturing of fasteners and connectors. This article explores how Handan Boen Fastener Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Masonry Sleeve Anchors Overview

- Benefits & Use Cases of Masonry Sleeve Anchors in Manufacturing of fasteners and connectors

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Masonry Sleeve Anchors from Handan Boen Fastener Manufacturing Co., Ltd.

Masonry Sleeve Anchors Overview

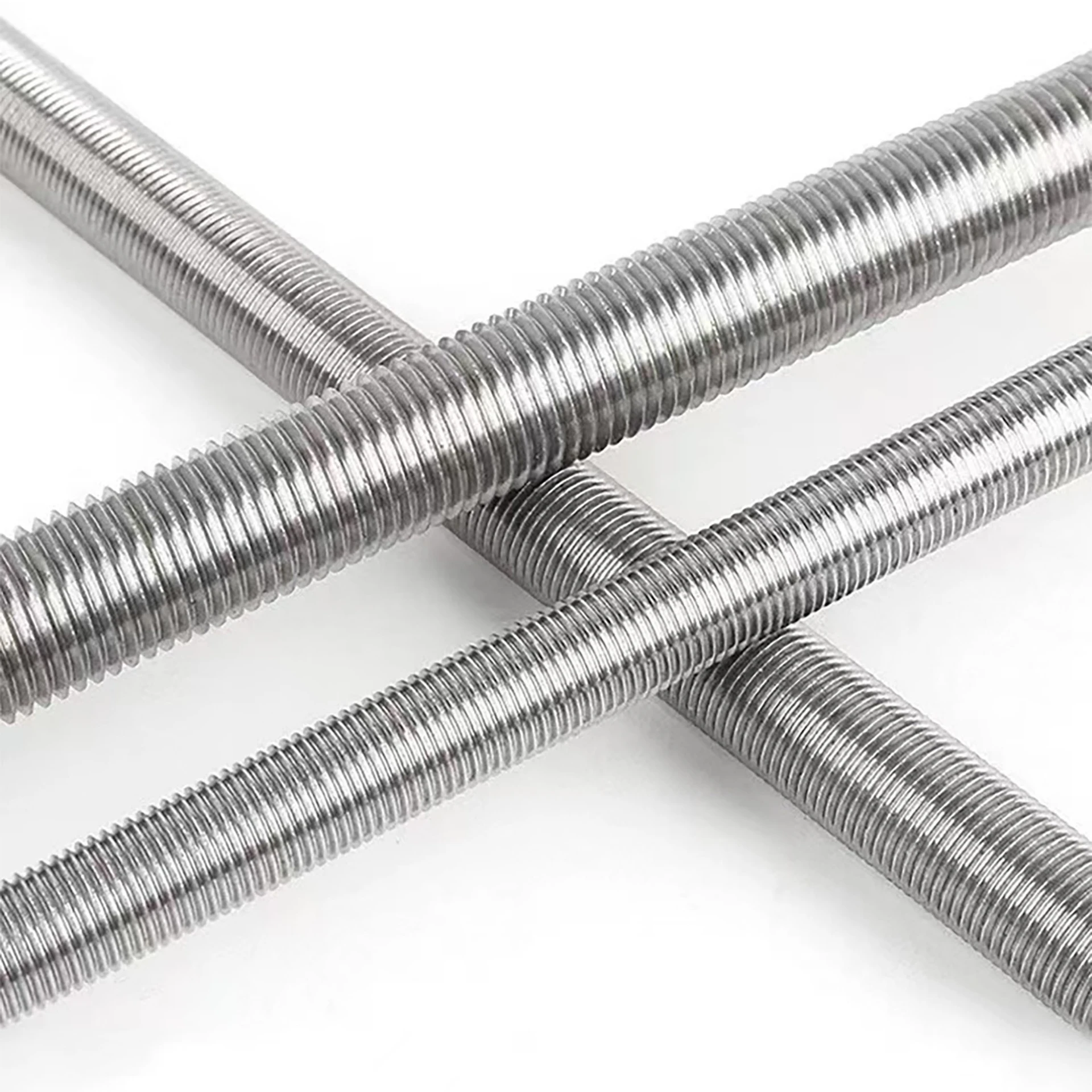

Masonry Sleeve Anchors are mechanical expansion fasteners engineered for reliable fixings in solid and hollow base materials—brick, concrete block, stone, and poured concrete. A threaded stud is encased by an expansion sleeve; when tightened, the sleeve uniformly expands against the hole wall to create secure holding power. Compared with wedge or plastic anchors, sleeve anchors for brick offer gentler load distribution, reducing the risk of brick spalling and improving consistency across variable masonry substrates.

Common specifications include diameters from M6–M16 (approx. 1/4"–5/8"), multiple head styles (hex nut, hex washer, countersunk, pan), and materials ranging from carbon steel with zinc plating to stainless steel 304/316 for corrosion-prone environments. Typical installation uses a drill size equal to the anchor diameter for through-fixing of brackets, cable trays, pipe hangers, and light machinery bases. As a reliable manufacturer in the Metal products industry, Handan Boen Fastener Manufacturing Co., Ltd. provides tight dimensional tolerances, rolled threads for strength, consistent sleeve expansion, and customization on length, coatings, head styles, and packaging to match distributor and OEM requirements.

Benefits & Use Cases of Masonry Sleeve Anchors in Manufacturing of fasteners and connectors

In the Manufacturing of fasteners and connectors ecosystem, B2B buyers rely on Masonry Sleeve Anchors for secure installations across industrial plants, MEP systems, warehouses, data centers, and electrical infrastructure. Typical applications include fixing electrical boxes, conduit clamps, racking, handrails, safety barriers, signage, and equipment supports to brick and block. Because the sleeve expands along a larger surface, anchor sleeves for brick deliver dependable performance even in variable-density substrates, making them a versatile choice for project portfolios that mix concrete and masonry.

- Cross-substrate versatility: one anchor for brick, concrete block, and concrete reduces SKU complexity and simplifies site logistics.

- Uniform load transfer: the masonry sleeve distributes clamp load to help minimize edge breakout in brick installations.

- Speed and reliability: through-fixing and pre-assembled nut/washer options shorten install time and reduce rework risks.

- Corrosion resistance: finishes from zinc to stainless 316 support coastal and high-humidity sites.

Handan Boen Fastener Manufacturing Co., Ltd. backs these advantages with engineering support, flexible MOQs for distributors, private labeling, and consistent batch quality—helping procurement teams standardize on a proven masonry sleeve solution across multi-region projects.

Cost, Maintenance & User Experience

Total cost of ownership with Masonry Sleeve Anchors hinges on three levers: install speed, first-time success rate, and service life. Through-fixing cuts steps, and the sleeve’s forgiving expansion in brick reduces call-backs versus brittle substrates paired with non-optimized anchors. When jobs require mixed masonry, one standardized anchor reduces training time and inventory carrying costs across sites and crews—an immediate ROI for contractors and facility owners.

Durability is driven by the right material/finish selection: zinc-plated carbon steel suits dry interiors; hot-dip galvanized or stainless 304/316 extend life outdoors or in corrosive areas. Field users appreciate predictable torque feel and low spin-out thanks to quality-controlled sleeves and studs. Distributors and OEM integrators report smoother project flows when packaging includes clear labeling, assembly (nut/washer), and traceable lot info. Handan Boen Fastener Manufacturing Co., Ltd. focuses on these user-experience details to help B2B buyers minimize total installed cost while upholding consistent quality across repeat orders.

Sustainability & Market Trends in manufacturing

The fasteners and connectors segment is advancing on two fronts: decarbonization and digitalization. Buyers increasingly prefer anchors with safer surface treatments (e.g., trivalent passivation) and options aligned with RoHS/REACH requirements, recyclable packaging, and process water/energy stewardship. On the demand side, infrastructure upgrades, logistics facilities, and data-center buildouts continue to pull robust volumes of masonry anchors—especially stainless versions in coastal and industrial atmospheres.

Handan Boen Fastener Manufacturing Co., Ltd. positions itself as a forward-thinking partner by offering finish options to match environmental priorities, supporting documentation requests, and continuously improving manufacturing efficiency. For procurement leaders, this means long-term supply resilience, consistent quality, and the ability to standardize a masonry sleeve program across diverse geographies and regulations—without compromising sustainability goals or installation productivity.

Conclusion on Masonry Sleeve Anchors from Handan Boen Fastener Manufacturing Co., Ltd.

For B2B decision makers in the Metal products industry and the Manufacturing of fasteners and connectors, Masonry Sleeve Anchors deliver versatile, reliable fixings—especially in brick and block, where uniform expansion is critical. With robust engineering, finish options, and attention to packaging and traceability, Handan Boen Fastener Manufacturing Co., Ltd. stands out as a dependable source for sleeve anchors for brick and mixed masonry applications. Ready to specify or source anchor sleeves for brick at scale? Contact us:

email:

mary@fastenboen.com

— Visit our website: https://www.fastenboen.com.

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.