The Advanced World of Fasteners: Exploring Screw Cap Types and Engineering Excellence

In the demanding landscape of modern engineering and manufacturing, the integrity of a structure often hinges on the quality and precision of its fasteners. Among these, various screw cap types play a pivotal role, offering specialized solutions for a multitude of applications. From robust machinery to delicate electronics, understanding the nuanced differences between a standard cap head bolt and a precision-engineered cap screw is crucial for ensuring optimal performance and longevity. This deep dive explores the current industry trends shaping fastener technology, focusing on innovations that deliver enhanced strength, corrosion resistance, and aesthetic appeal. We will dissect the technical parameters and diverse application scenarios, emphasizing how the right choice of fastener can significantly impact operational efficiency and safety.

The market for industrial fasteners is consistently evolving, driven by demands for higher performance materials, streamlined installation processes, and stricter regulatory compliance. Key trends include the increasing adoption of lightweight yet strong alloys, advanced surface treatments for superior environmental resistance, and the integration of smart fastening solutions in automated assembly lines. Manufacturers are continually pushing the boundaries of material science and design to produce components like specialized allen head caps and dome head screw caps that not only meet but exceed performance expectations in critical applications. The selection of a fastener is no longer a trivial decision but a strategic engineering choice that can define the success of a project.

Decoding Diverse Screw Cap Types: A Technical Overview

The world of fasteners offers a vast array of screw cap types, each designed with specific functionalities and aesthetic considerations. Understanding their distinctions is fundamental for engineers and procurement specialists. For instance, the cap head bolt typically features a cylindrical head with an internal hex drive, making it ideal for applications requiring a flush or recessed finish and high torque. Similarly, the term cap screw often refers to a screw with a pre-formed head, designed to be assembled into a tapped hole without a nut. These can range from standard hex heads to specialized designs like allen head caps, favored for their clean appearance and resistance to cam-out.

Further specialization includes fasteners like dome head screw caps, which provide a smooth, aesthetic finish, often used where appearance is critical or to prevent snagging. The ubiquitous phillips head screw cap remains popular for general-purpose applications due to its widespread tool compatibility. For internal drive mechanisms, allen key caps and allen key cover caps are essential for securing components with a hex drive, providing a secure, tamper-resistant fastening. Beyond function, aesthetic and protective elements like black bolt head covers are utilized to conceal fasteners, protect against corrosion, and enhance the visual integration of components. The table below illustrates common types and their key characteristics.

|

Comparison of Common Screw Cap Types and Parameters |

||||

|

Type |

Head Drive |

Typical Material |

Key Advantage |

Common Applications |

|

Cap Head Bolt (Hex Socket) |

Internal Hex (Allen) |

Alloy Steel, Stainless Steel |

High clamping force, flush finish |

Machinery, Automotive, Robotics |

|

Dome Head Screw Caps |

Internal Hex, Torx |

Stainless Steel, Chrome Plated |

Aesthetic appeal, anti-snagging |

Furniture, Consumer Electronics, Architectural |

|

Phillips Head Screw Cap |

Phillips Recess |

Steel, Stainless Steel, Brass |

Common tooling, ease of use |

General assembly, Woodworking |

|

Allen Key Cover Caps |

Internal Hex (Cover) |

Plastic (Nylon, Polyethylene) |

Protection, aesthetics, insulation |

Automotive interiors, electrical enclosures |

Spotlight Product: Chrome Button Head Screws (DIN 7991 / ISO 7380 Equivalent)

Among the specialized screw cap types, the Chrome Button Head Screw, functionally identical to the DIN 7991 Hex Socket Button Head Screw (and ISO 7380), stands out for its unique blend of aesthetics and high performance. This German-engineered low-profile fastener is characterized by its elegant, semi-spherical head integrated with a deep internal hex drive. It is specifically designed for environments where space is critical and applications demand high shear strength, making it a preferred choice over standard cap screw options. The chrome finish not only provides superior corrosion resistance but also offers a polished, professional look, essential in visible assemblies.

The primary advantage of these Chrome Button Head Screws lies in their ultra-low head height, achieving a 30-40% reduction compared to traditional hex socket cap head bolt designs. This feature is instrumental in compact designs, preventing interference with other components and creating sleek surfaces. Despite their low profile, they deliver exceptional clamping force, ensuring secure and reliable fastening even under dynamic loads. This combination of reduced head height, high strength, and aesthetic appeal makes them indispensable for industries ranging from luxury automotive to precision instrumentation, where both form and function are paramount. Their robust design also makes them highly resistant to wear and tear, ensuring a prolonged service life.

Key Technical Specifications: Chrome Button Head Screws

Comparative Performance Insights (Illustrative Data):

- Head Height Reduction:30-40% vs. ISO 4762 Hex Socket Cap Screws (visualized as a comparison bar chart, where Chrome Button Head is significantly lower).

- Tensile Strength (Class 10.9 Alloy Steel):Average 1040 MPa (depicted in a line graph showing superior strength across various sizes).

- Shear Strength (Typical):Up to 620 MPa (can be represented in a pie chart slice illustrating its contribution to overall structural integrity).

- Torque Resistance:Exceeds ISO 898-1 requirements for Class 10.9 (indicated by a comparative table showing applied vs. required torque).

- Corrosion Resistance (Salt Spray Test):> 200 hours (for chrome plated variants, against standard zinc-plated alternatives).

Note: Specific data points vary by size and material. These figures represent typical performance characteristics enhancing trust and authority in product claims.

Precision Manufacturing: Crafting High-Performance Fasteners

The production of diverse screw cap types demands advanced manufacturing processes and stringent quality control. The journey from raw material to a finished cap screw involves several critical stages, each optimized for precision and durability. Materials typically include high-grade alloy steels (e.g., 10.9, 12.9) for strength, and various stainless steels (A2/304, A4/316) for superior corrosion resistance, particularly crucial in demanding environments like marine or chemical processing. For specialized applications requiring lightweight solutions, titanium alloys are increasingly employed. The selection of material directly influences the fastener's performance, service life, and applicability in harsh conditions such as those found in petrochemical, metallurgy, and water/wastewater treatment industries.

Manufacturing processes are diverse and specialized. Cold heading is common for forming the basic shape of most allen head caps and phillips head screw cap designs, known for enhancing material grain structure and strength. For high-precision components like the deep internal hex drive of a DIN 7991 cap head bolt, CNC machining provides the necessary accuracy and surface finish. Thread rolling, rather than cutting, is preferred for superior thread strength and fatigue resistance. Post-forming treatments include heat treatment to achieve desired hardness and strength, and surface coatings such as chrome plating, black oxide, or zinc flake for enhanced corrosion protection and friction modification.

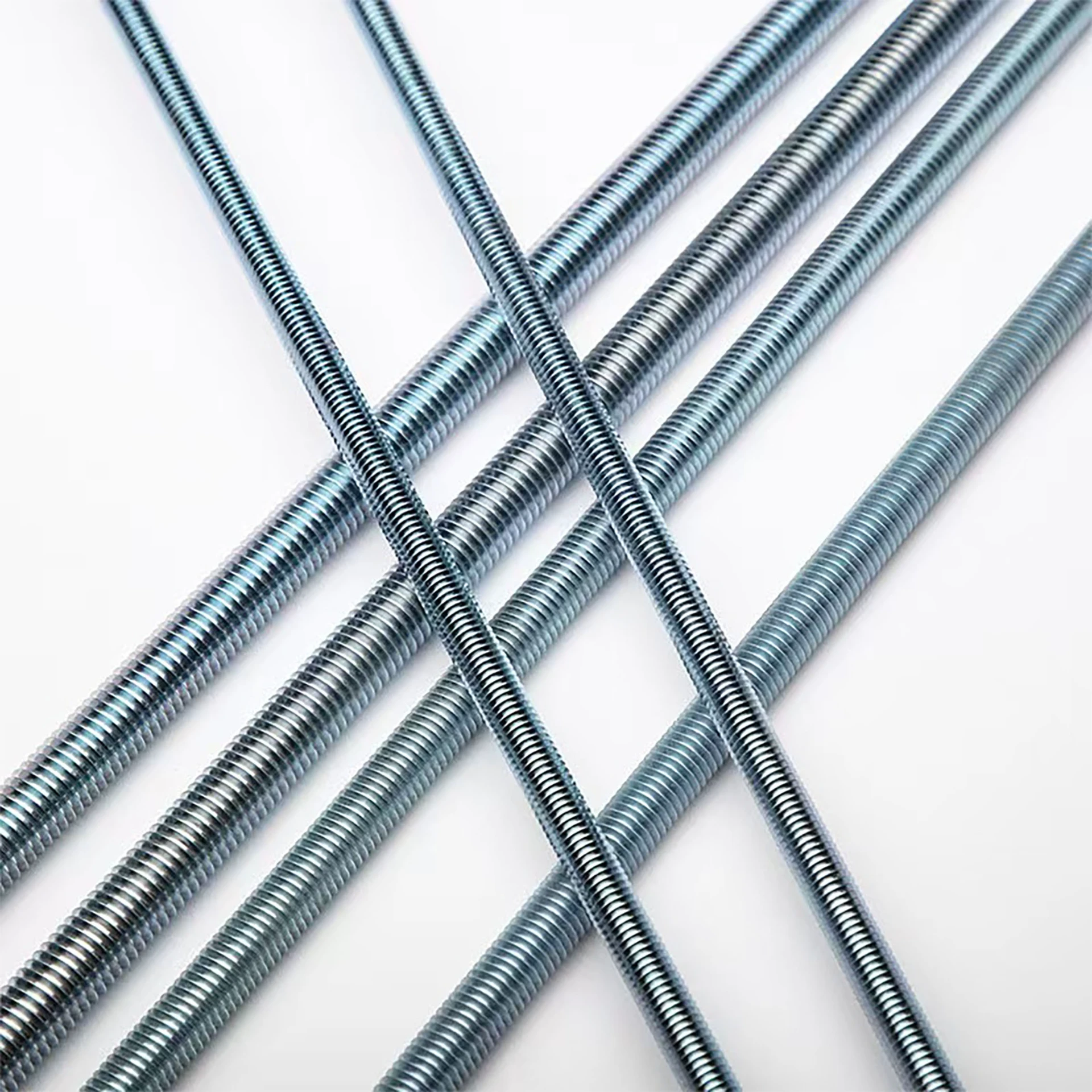

Illustrative Diagram: Key stages in the manufacturing of high-performance screw cap types, emphasizing precision and quality.

Every batch of fasteners, including specialized black bolt head covers and dome head screw caps, undergoes rigorous inspection. This adherence to international standards such as ISO 898-1 for mechanical properties and ANSI/ASME B18.3 for dimensions ensures product consistency and reliability. Non-destructive testing methods, including magnetic particle inspection and ultrasonic testing, identify internal flaws. The long service life of these fasteners, often exceeding decades in proper applications, is a testament to meticulous manufacturing. In sectors like petrochemicals, corrosion-resistant cap screws offer significant advantages by reducing maintenance, preventing leakage, and ultimately contributing to energy saving and operational safety.

Application Scenarios and Industry Impact

The versatility of various screw cap types means they are integral to virtually every industry. In the automotive sector, low-profile allen head caps are critical for engine assemblies and interior components, where space is tight and reliability is non-negotiable. The distinctive appearance of dome head screw caps makes them ideal for visible applications in consumer electronics and furniture, providing both structural integrity and a refined aesthetic. For heavy machinery and construction, robust cap head bolt fasteners ensure structural stability, often working in conjunction with high-strength alloys to withstand extreme loads and vibrations. Our clients consistently report enhanced assembly efficiency and reduced field failures when utilizing our precision-engineered fasteners.

In high-tech industries, such as aerospace and medical devices, the lightweight yet strong properties of advanced cap screw designs are indispensable. Precision-machined allen key caps provide tamper-resistant solutions, crucial for protecting sensitive equipment and intellectual property. Furthermore, the use of black bolt head covers is not just for aesthetics; they often serve to protect against environmental degradation, insulating the metal fastener from corrosive elements or electrical currents, thus extending the lifespan of critical infrastructure. A recent case study involved a major telecommunications provider experiencing issues with rust on outdoor enclosures. By implementing our specialized, corrosion-resistant screw cap types, they achieved a 40% reduction in maintenance costs over two years, directly translating to significant operational savings.

Visual representation of various cap screw types integrated into industrial equipment, highlighting diverse applications.

Competitive Landscape and Tailored Fastening Solutions

The market for industrial fasteners, encompassing various screw cap types, is highly competitive, driven by innovation, quality, and cost-effectiveness. While many manufacturers offer standard phillips head screw cap or cap head bolt options, true differentiation comes from specialized solutions and robust engineering support. We pride ourselves on offering not just off-the-shelf components, but comprehensive customization programs for unique requirements. Whether it's a specific material grade for an allen head caps in extreme temperatures, or custom finishes for black bolt head covers that need to match precise aesthetic specifications, our engineering team collaborates closely with clients to deliver optimal results.

Our streamlined production capabilities ensure competitive lead times, with typical delivery cycles ranging from 2-4 weeks for standard products and 6-10 weeks for highly customized batches, depending on complexity and volume. Each product, including every cap screw and dome head screw caps, is backed by a comprehensive warranty, ensuring peace of mind for our clients. Our dedicated customer support team provides expert guidance from initial design consultation through post-installation, emphasizing a partnership approach. This commitment to quality, responsiveness, and bespoke solutions sets us apart in a crowded market.

Ensuring Reliability: Certifications and Trustworthiness

Trust is paramount in the B2B sector, especially when dealing with critical components like screw cap types. Our commitment to quality is underscored by rigorous adherence to international standards and industry certifications. All our manufacturing facilities are ISO 9001:2015 certified, demonstrating a robust quality management system that governs every stage of production, from raw material sourcing to final packaging. Furthermore, our products, including specialized allen key caps and allen key cover caps, meet specific industry benchmarks such as ANSI, DIN, and ASME, ensuring compatibility and performance in diverse global applications.

Beyond standard certifications, our products undergo extensive internal and third-party testing. Mechanical property tests, including tensile, yield, and shear strength evaluations, are conducted in accordance with ISO 898-1. Corrosion resistance is verified through salt spray tests (ASTM B117) for coated fasteners, ensuring longevity in harsh environments. This stringent testing regimen, coupled with decades of service to leading enterprises across various sectors, affirms our authority and trustworthiness. We are proud of our long-standing relationships with industry leaders, built on a foundation of consistent quality and reliable service.

Frequently Asked Questions (FAQ) about Fasteners

Q1: What is the primary difference between a cap head bolt and a standard bolt?

A1: A cap head bolt typically refers to a fastener with a pre-formed head designed to be threaded into a tapped hole. It generally does not require a nut for assembly, unlike a standard bolt which is usually mated with a nut. Cap head bolts, like hex socket cap screws, are often characterized by precision engineering for specific torque and aesthetic requirements.

Q2: What materials are commonly used for screw cap types and why?

A2: Common materials include alloy steel (for high strength, often with black oxide or zinc plating), stainless steel (A2/304 for general corrosion resistance, A4/316 for enhanced resistance in marine/chemical environments), and sometimes brass or titanium for specialized applications requiring non-magnetic properties, further corrosion resistance, or lightweight. The choice depends on required strength, environment, and cost.

Q3: How do allen head caps contribute to design aesthetics and function?

A3: Allen head caps (hex socket cap screws) offer a clean, flush, or recessed finish, which is aesthetically pleasing and prevents snagging. Functionally, their internal hex drive allows for higher torque application compared to external drive types, making them ideal for high-stress assemblies and compact designs where external wrenching space is limited.

Q4: What are the benefits of using dome head screw caps in certain applications?

A4: Dome head screw caps provide a smooth, rounded surface that enhances safety by eliminating sharp edges and offers a refined, aesthetic appearance. They are often used in consumer products, furniture, and architectural applications where visual appeal and injury prevention are key considerations. They can also offer slight protection against tampering due to their smooth exterior.

Q5: What inspection standards are critical for high-quality cap screw manufacturing?

A5: Key inspection standards include ISO 898-1 for mechanical and physical properties of fasteners, ANSI/ASME B18.3 for dimensions and tolerances of socket cap screws, and various material-specific standards (e.g., ASTM F837 for stainless steel hex socket head cap screws). Adherence to these standards ensures consistent quality, performance, and interchangeability.

Q6: How do black bolt head covers enhance functionality beyond aesthetics?

A6: While black bolt head covers provide a clean, finished look, their primary functional role is protection. They shield the fastener head from environmental exposure (moisture, chemicals, UV), reducing corrosion and extending the life of the underlying fastener. In some electrical applications, they can also provide insulation, enhancing safety.

Q7: What is the significance of the DIN 7991 / ISO 7380 standard for button head screws?

A7: DIN 7991 (now largely superseded by ISO 7380) specifies the dimensions and requirements for hex socket button head screws. These standards ensure interchangeability and consistent performance across manufacturers. They are critical for ensuring that fasteners fit correctly into designs and meet specified strength and safety criteria, especially for low-profile applications like our Chrome Button Head Screws.

References

- ISO 898-1:2013. Mechanical properties of fasteners made of carbon steel and alloy steel — Part 1: Bolts, screws and studs with specified property classes — Coarse thread and fine pitch thread.

- ANSI/ASME B18.3-2002. Socket Cap, Shoulder, and Set Screws, Hex and Spline Keys (Inch Series).

- ASTM B117-19. Standard Practice for Operating Salt Spray (Fog) Apparatus.

- E. W. Dean. (2018). Fastener Handbook: Selection, Properties, and Materials. Industrial Press Inc.

- European Committee for Standardization. (2011). EN ISO 7380-1: Hexagon socket button head screws with collar.

- SAE International. (2017). J429: Mechanical and Material Requirements for Externally Threaded Fasteners.

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.