Hot-Dipped Galvanized Steel Turnbuckles

Turnbuckles are used for tensioning steel wires and adjusting their tightness. Among them, the OO type is suitable for applications where disassembly is infrequent, the CC type is designed for frequent disassembly, and the CO type is used when one end requires regular disassembly while the other end does not.

Based on the manufacturing process, turnbuckles are primarily categorized into three types: cast malleable iron, ordinary carbon steel, and forged. The current market mainly offers ordinary carbon steel and forged varieties. Surface treatments, typically electropla

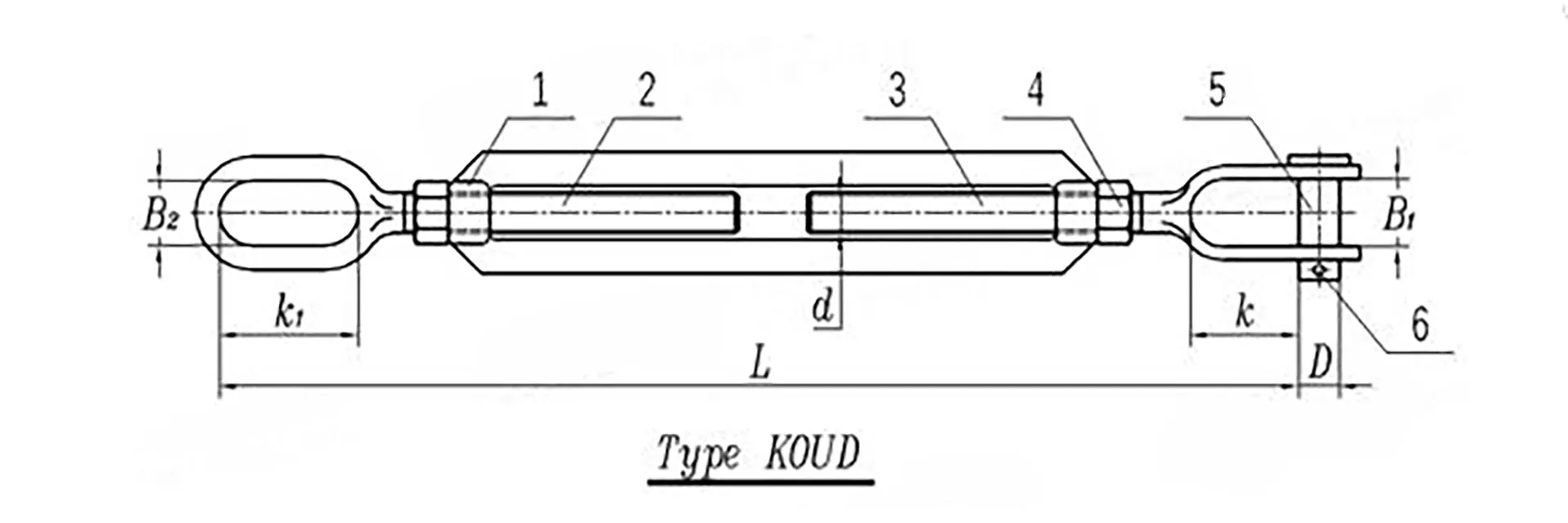

Specifications and Functions

The turnbuckle allows flexible adjustment of steel wire tension through the extension and retraction of its lead screw, making it highly suitable for bundling and securing components during transportation, as well as for alignment during installation. It consists of an adjustment rod with left-hand and right-hand threads, nuts, and a tie rod, and is equipped with an anti-theft and anti-loosening device to ensure operational safety.

The device is operated using a dedicated socket. After disassembly, it does not need to be removed; instead, the guide plate ring can be slid along the tie rod to easily adjust its position, enabling convenient operation. With its simple structure, ease of processing, cost-effectiveness, and high practicality, it is particularly well-suited for power line construction, especially for positioning stay rods on high-voltage transmission towers.

ting or hot-dip galvanizing, are applied to prevent rust and corrosion.

Specifications and Functions

The turnbuckle allows flexible adjustment of steel wire tension through the extension and retraction of its lead screw, making it highly suitable for bundling and securing components during transportation, as well as for alignment during installation. It consists of an adjustment rod with left-hand and right-hand threads, nuts, and a tie rod, and is equipped with an anti-theft and anti-loosening device to ensure operational safety.

The device is operated using a dedicated socket. After disassembly, it does not need to be removed; instead, the guide plate ring can be slid along the tie rod to easily adjust its position, enabling convenient operation. With its simple structure, ease of processing, cost-effectiveness, and high practicality, it is particularly well-suited for power line construction, especially for positioning stay rods on high-voltage transmission towers.

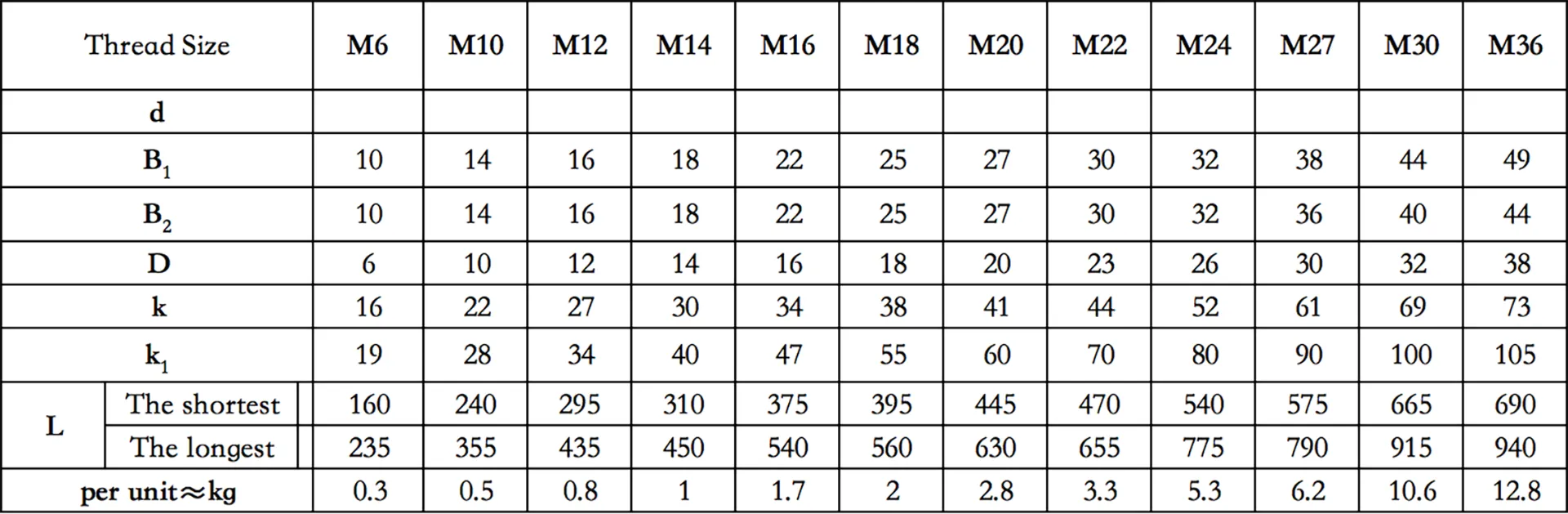

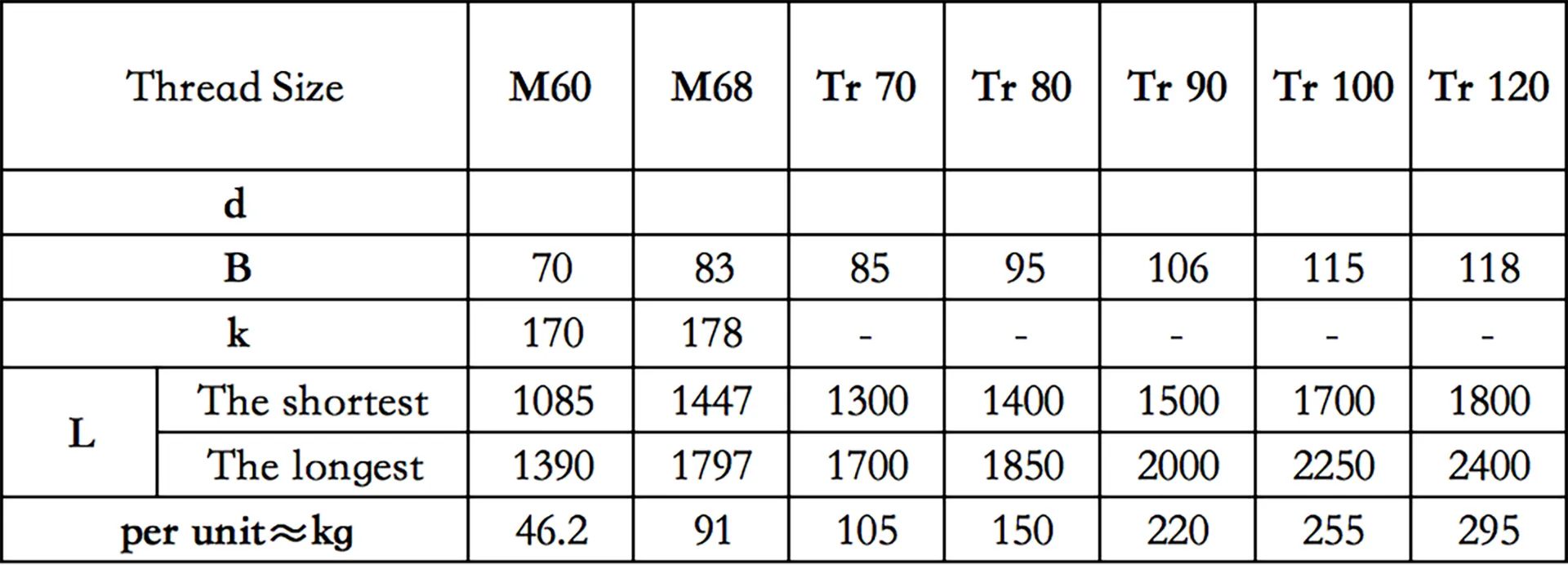

PARAMETER

SERIVCE

Reliable After-Sales Support

Swift resolution for all technical issues & product inquiries.

20+ Years of Global Export Expertise

Proven experience in international logistics & compliance.

Detailed Product Specifications On Request

Customizable spec sheets for informed purchasing decisions.

Instant Quote Response

Submit inquiries for prompt pricing & solution proposals.

Certified Export Documentation & Timely Shipment

Hassle-free logistics with professionally prepared export papers.

Custom Packaging with Pre-Shipment Visual Verification

Branded/secure packaging with photo confirmation before dispatch.

Premium Quality at Competitive Pricing

Industry-leading products optimized for value & performance.

CONTACT US

HANDAN BOEN FASTENERS MANUFACTURING CO.,LTD

Email:shaun@boenfasteners.com

Wechat/WhatsApp/Skype/zalo:+86 13293070568 / +86 15630072814