Countersunk Head

Countersunk bolt types are designed with a flat or slightly rounded head that sits flush with the surface when installed, creating a smooth finish. This feature makes them ideal for applications where appearance, safety, and aerodynamics are important. Common variations include the anchor bolt countersunk head, bolt countersink, counter head allen bolt, counter head bolt, counter head rivet, and counter head screw.

The anchor bolt countersunk head provides secure anchoring in concrete or masonry while maintaining a flush finish, often used in construction and infrastructure projects. A bolt countersink refers to the precise machining of a hole so the fastener head sits level with or below the surface, essential for achieving a professional look in metal and wood applications.

Counter head allen bolts and counter head bolts feature a countersunk design with different drive types, offering both strength and easy installation in equipment assembly or structural frameworks. Counter head rivets are permanent fasteners used when vibration resistance and a smooth profile are needed, while counter head screws combine countersinking with the convenience of removable fastening.

Available in materials like stainless steel, carbon steel, and titanium, these fasteners provide both mechanical strength and corrosion resistance. They are widely used in industries such as aerospace, marine, automotive, furniture manufacturing, and architectural design. Choosing the right countersunk bolt type ensures both functional reliability and a clean, finished appearance.

Why Would You Use A Countersunk Screw

Countersunk screws are specifically designed to sit flush with or below the surface of the material once installed, making them highly valuable in applications where a smooth finish or minimal obstruction is required. The head of a countersunk screw has a conical shape that fits into a matching countersink hole, allowing the top of the screw to align seamlessly with the surrounding surface. One of the main reasons to use a countersunk screw is aesthetics. In woodworking, cabinetry, and furniture making, these screws provide a clean, professional look without raised fastener heads. This also prevents snagging or interference with other components. In metalworking and industrial design, countersunk screws are chosen to maintain flush surfaces for sliding parts, covers, or enclosures. Functionality is another key benefit. By sitting flush, countersunk screws eliminate protrusions that could disrupt mechanical movement, airflow, or sealing. In aerospace, automotive, and marine industries, this helps reduce drag, improve aerodynamics, and ensure safety by preventing parts from catching on exposed fastener heads. Additionally, countersunk screws distribute load more evenly across the joint when tightened, reducing stress concentrations around the fastener hole. This enhances durability and prevents material deformation in softer substrates like wood, plastic, or aluminum. In short, countersunk screws are used not only for appearance but also for safety, performance, and functionality in applications where a smooth, streamlined surface is critical.

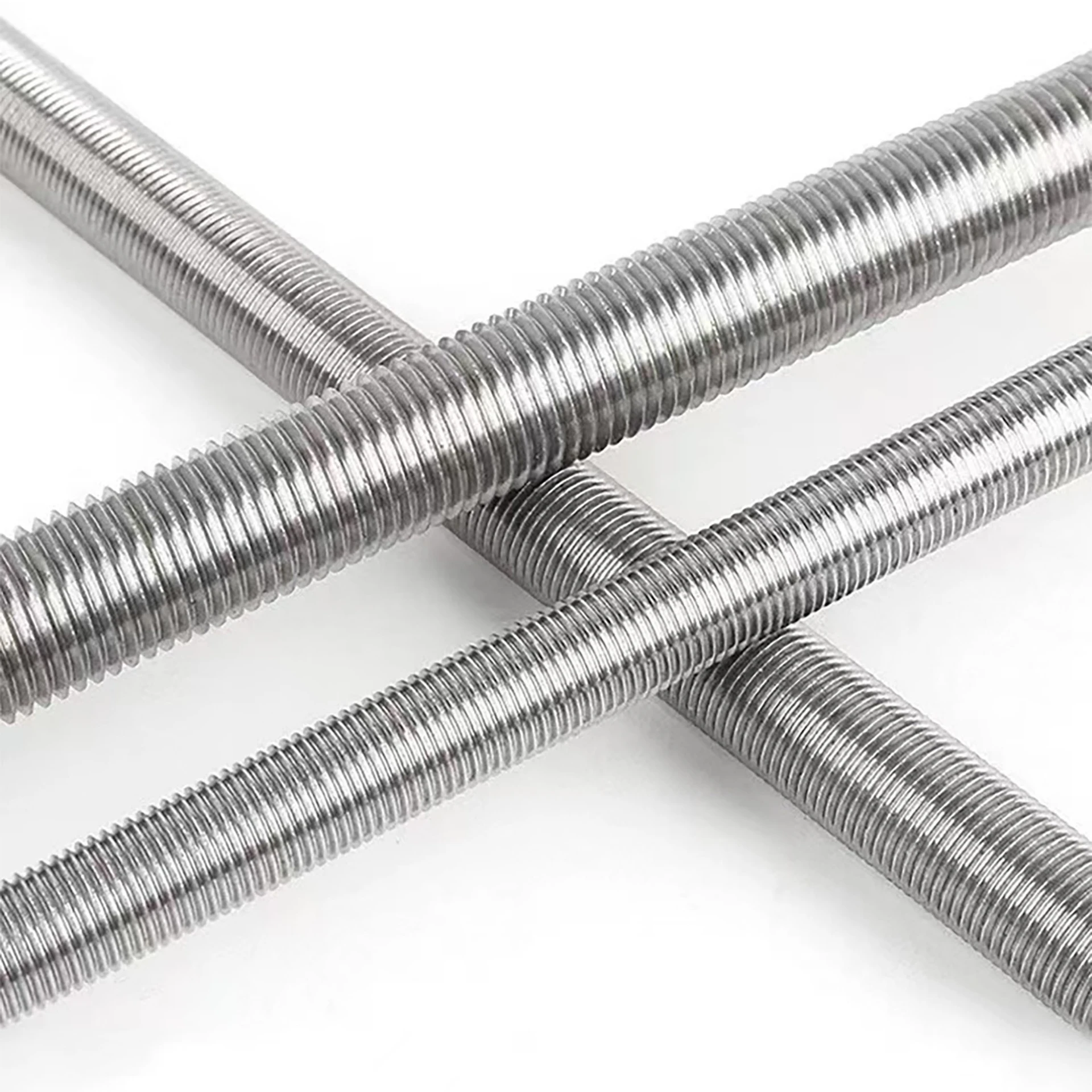

Countersunk Bolt Types

The world of countersunk bolt types offers solutions for projects that require both secure fastening and a flush, smooth surface. The anchor bolt countersunk head is designed for structural anchoring into concrete or masonry, combining strength with a low-profile finish.

The bolt countersink process ensures that the fastener head sits flush with the material surface, which is essential for both functional and aesthetic reasons. This is especially important in woodworking, metal fabrication, and applications where moving parts should not catch on protruding fasteners.

Counter head allen bolts and counter head bolts bring versatility, offering internal or external drive options for easy installation and high torque resistance. For permanent fastening needs, counter head rivets provide a tamper-resistant, vibration-proof solution. Meanwhile, counter head screws combine the flush finish of countersinking with the advantage of easy removal and replacement.

By understanding the differences among these types, engineers and buyers can select the ideal fastener for mechanical, structural, or decorative purposes. With the right materials and precision manufacturing, countersunk bolts enhance both performance and appearance in any industry.

Exploring the Key Countersunk Bolt for Modern Applications

-

Anchor Bolt Countersunk Head

Securely anchors into concrete or masonry while maintaining a flush finish for safety and aesthetics. -

Bolt Countersink

A machining process that allows bolts to sit level with or below the surface for a clean appearance. -

Counter Head Allen Bolt & Counter Head Bolt

Versatile fastening options with high torque resistance, available in multiple drive styles. -

Counter Head Rivet & Counter Head Screw

Permanent or removable fastening solutions that combine low-profile design with reliability and durability.