Countersunk Phillips Tri-Lobular Screw | Self-Tapping | Zinc

Countersunk Phillips Tri-Lobular Thread ScrewEngineered for flush-mount applications requiring vibration-proof fastening. The countersunk head provides a smooth surface finish, while the Phillips drive ensures efficient torque transfer. Tri-lobular thread technology creates permanent mechanical locking through cold-forming deformation, excee

ding ISO 16130 vibration resistance standards. Ideal for aerospace, precision instruments, and automotive chassis.

Key Features

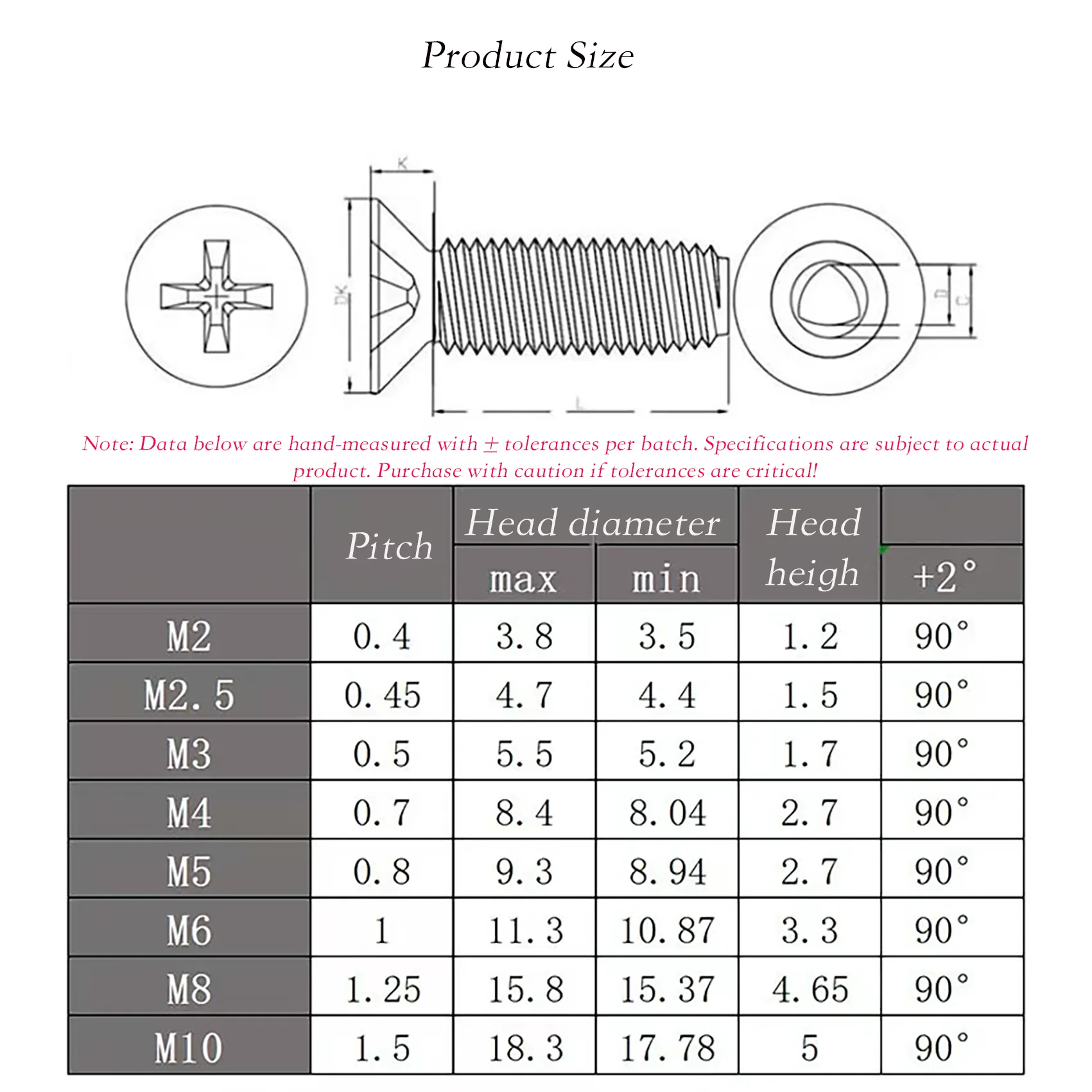

✅ Flush Surface:90°±2° head angle (ISO 10642) for seamless embedding

✅ Zero Loosening:Residual clamping force >85% after 50,000 vibration cycles

✅ High Torque Transfer:Phillips drive compatible with ISO 8764-1 PH bits, 1.5x cam-out resistance vs

standard screws

✅ Military-Grade Materials:Ti6Al4V titanium / Alloy steel Grade 12.9 / A4-80 stainless steel

Technical Data

|

Parameter |

Specification |

|

Head Angle |

90° (ISO 10642) / 100° (ANSI) |

|

Thread Standard |

Tri-Lobular Thread (ISO 15480) |

|

Diameter |

M3 - M10 |

|

Countersink Tol. |

±0.1mm (Base material ≥2mm) |

|

Standard |

GB6561 |

Parameter

Key Applications:

Tri-Lobular Thread Screws leverage their tri-lobular thread cold-forming locking mechanism to address fastener loosening failures caused by high-frequency vibration/dynamic loads. They are indispensable in the following fields:

|

Industry |

Typical Application |

Failure Consequence |

Solution |

|

Automotive |

Engine mounts, Transmission housings |

Bolt loosening may trigger accidents |

M8-M12 high-strength tri-lobular screws (Grade 10.9) |

|

Rail Transport |

Railway signaling equipment, Carriage connectors |

Vibration-induced control system failure |

A4 stainless steel tri-lobular screws + Anticorrosive coating |

|

Aerospace |

Avionics equipment brackets |

Extreme vibration causing device displacement |

Titanium alloy tri-lobular screws (40% weight reduction) |

|

Industrial Robots |

Joint bearing fixation units |

Micromovement from repetitive motion |

M4-M6 micro-sized tri-lobular screws |

SERIVCE

Reliable After-Sales Support

Swift resolution for all technical issues & product inquiries.

20+ Years of Global Export Expertise

Proven experience in international logistics & compliance.

Detailed Product Specifications On Request

Customizable spec sheets for informed purchasing decisions.

Instant Quote Response

Submit inquiries for prompt pricing & solution proposals.

Certified Export Documentation & Timely Shipment

Hassle-free logistics with professionally prepared export papers.

Custom Packaging with Pre-Shipment Visual Verification

Branded/secure packaging with photo confirmation before dispatch.

Premium Quality at Competitive Pricing

Industry-leading products optimized for value & performance.

CONTACT US

HANDAN BOEN FASTENERS MANUFACTURING CO.,LTD

Email:shaun@boenfasteners.com

Wechat/WhatsApp/Skype/zalo:+86 13293070568 / +86 15630072814