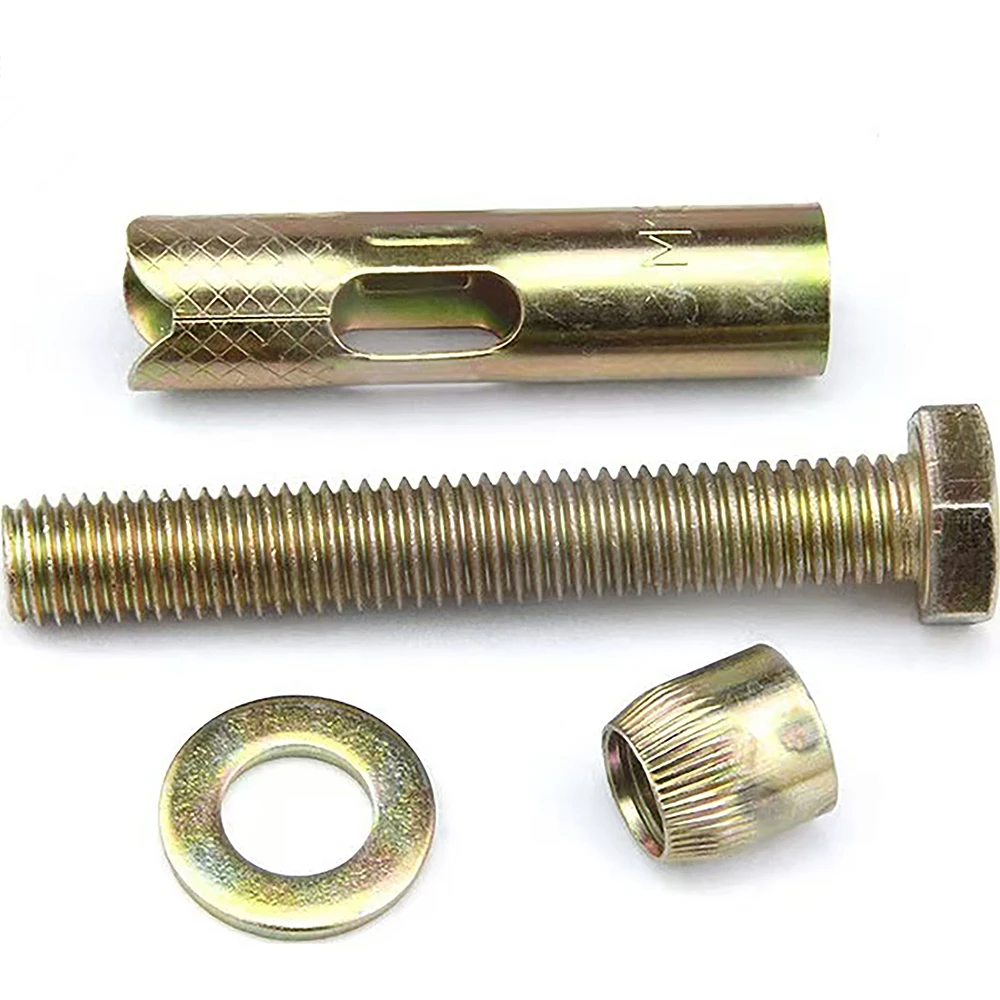

Heavy Duty Concrete Anchors

1. Anti-Rotation Design

Fluted sleeve surface bites into concrete

Eliminates spin-out during tightening (per ISO 16047)

95% torque retention vs. 40-60% in smooth anchors

2. Vibration Resistance

Withstands >10⁶ cyclic loads (ISO 16130 certified)

Ideal for: CNC machines, conveyor systems, rail tracks

3. Enhanced Grip Strength

Ribbed shank increases pull-out resistance by 35%

Test data: M10 anchor → 17.2 kN vs. smooth sleeve 12.7 kN (ASTM E488)

4. Corrosion Protection

Zinc-plated carbon steel (ISO 4042 compliant)

Salt spray resistance: 500+ hours (ISO 9227)

5. Installation Efficiency

No pre-drilling required for ribs

Single-step expansion: Drill → Insert → Tighten

Key Applications:

High-Vibration Machinery: CNC bases, compressor mounts / Structural Steel Connections: Steel column base plates (AISC 360)

Critical Infrastructure: Bridge expansion joints, seismic bracing / Outdoor Equipment: Cell tower foundations, solar racking

SERIVCE

Reliable After-Sales Support:Swift resolution for all technical issues & product inquiries. / 20+ Years of Global Export Expertise:Proven experience in international logistics & compliance.

Detailed Product Specifications On Request:Customizable spec sheets for informed purchasing decisions. / Instant Quote Response:Submit inquiries for prompt pricing & solution proposals.

Certified Export Documentation & Timely Shipment:Hassle-free logistics with professionally prepared export papers.

Custom Packaging with Pre-Shipment Visual Verification:Branded/secure packaging with photo confirmation before dispatch.

Premium Quality at Competitive Pricing: Industry-leading products optimized for value & performance.