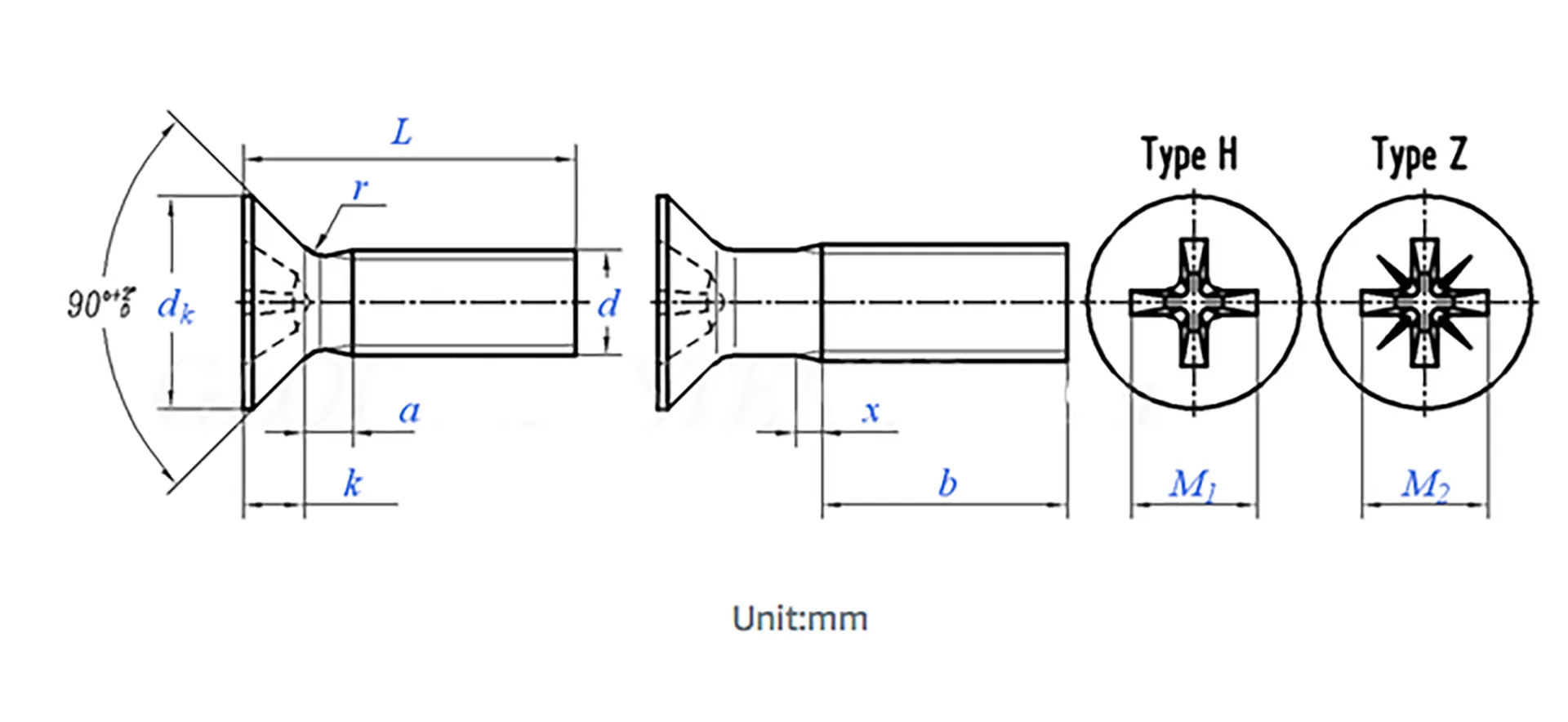

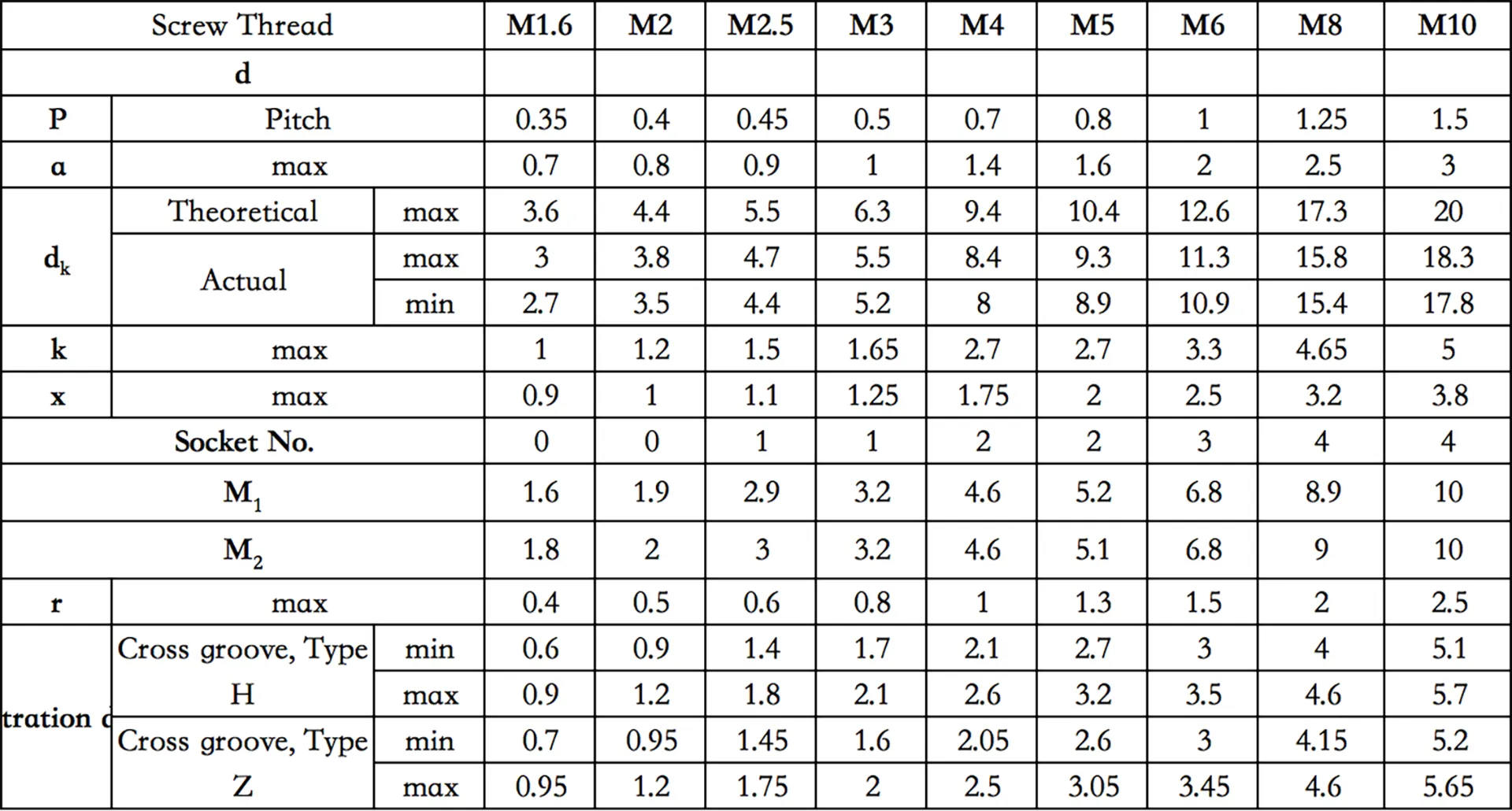

M3-M8 Phillips Flat Head Screws GB/T 819 countersunk head screws

Screw Core Standards & Structural Features Comparison Table

|

Parameter |

Chinese Standard (GB/T 819) |

International Equivalent |

Key Specifications |

|

Head Type |

Countersunk (82° or 90° cone angle) |

DIN 965 / ISO 10642 |

Cone angle must strictly match mounting hole design |

|

Drive Type |

Cross recess (Phillips) |

JIS B 1111 |

Recess depth must be compatible with driver bits |

|

Thread Type |

Machine thread (Metric coarse/fine) |

ISO 261 / ISO 262 |

Fine threads (e.g., M8×1) require explicit notation |

|

Material Grade |

Carbon Steel: 4.8/8.8/12.9 |

ASTM A574 (Cl.12.9) |

Grade 12.9 = ultra-high strength (aerospace grade) |

|

|

Stainless Steel: A2-70/A4-80 |

SAE J429 (Grade 8) |

A4-80: acid-resistant SS; SAE J429: US high-strength |

|

Surface Treatment |

Zinc plating (blue/color), Black oxide |

ASTM B633 (Zn-Fe alloy) |

Color zinc > blue zinc corrosion resistance; Black oxide = rust prevention |

Parameter

Key Applications:

Mechanical Assembly

Used for joining metal/plastic components requiring a flush surface (e.g., instrument housings, gearbox cover plates).

The countersunk design prevents screw protrusion, eliminating mechanical interference or risks of operators being scratched.

Electronics and Electrical Equipment

Securing PCB brackets, heat sinks, or device panels (e.g., computer chassis, power supply enclosures).

The flush surface facilitates labeling or applying insulating materials.

Furniture Assembly

Connecting metal hinges, slides, or reinforcement parts (e.g., office chair bases, filing cabinet internals).

Concealed installation enhances aesthetic appeal.

Automotive/Aerospace Components

Mounting interior trim panels, sensor brackets, and other non-load-bearing structures.

Requires thread-locking adhesives or washers to withstand vibrational environments.

Building Hardware

Fastening door/window fittings, ceiling joists, and other thin-walled metal components.