Full Nut, Hex Strength—M6 & M8 Options: Why Choose Us?

full nut,m6 full nut,m8 full nut,full nut nut,hex full nut is a key solution in the hardware industry, specifically within fastener and nut. This article explores how Handan Boen Fastener Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- full nut,m6 full nut,m8 full nut,full nut nut,hex full nut Overview

- Benefits & Use Cases of full nut,m6 full nut,m8 full nut,full nut nut,hex full nut in nut

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in hardware

- Conclusion on full nut,m6 full nut,m8 full nut,full nut nut,hex full nut from Handan Boen Fastener Manufacturing Co., Ltd.

full nut,m6 nut,m8 nut,full nut nut,hex full nut Overview

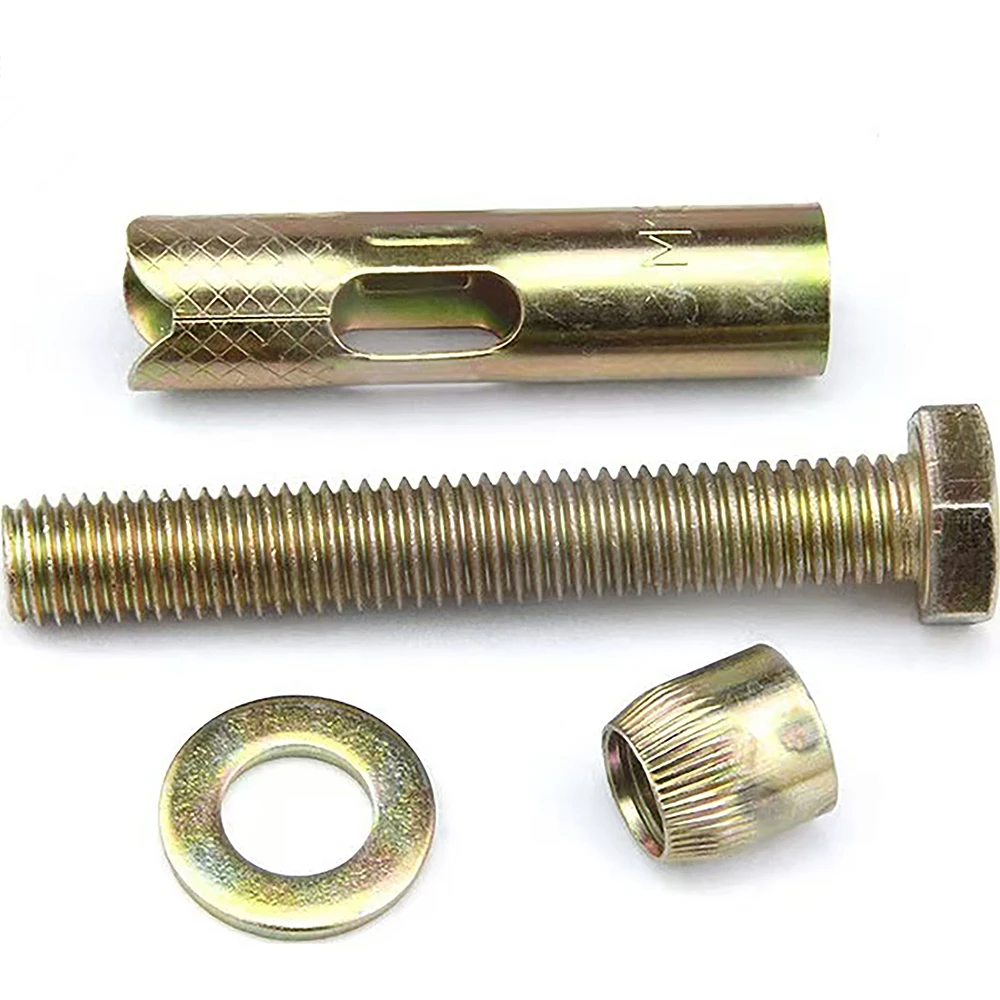

Within the fastener universe, a hex nut is the workhorse that delivers secure, repeatable clamping force across machinery, steel structures, electrical cabinets, and more. Typically manufactured to ISO 4032/DIN 934 (ASME B18.2.2 equivalents for inch threads), the nut provides the thread engagement length needed to achieve specified proof loads and long-term joint reliability. Common specifications include metric sizes from M3–M48, with high-demand items like the m6 nut and m8 nut supporting broad OEM and MRO needs. Threads are usually produced to ISO 6H tolerance, with materials ranging from carbon steel (property classes 5, 8, 10) to stainless steel (A2-70/A4-70) and optional brass.

Handan Boen Fastener Manufacturing Co., Ltd. supplies hex nut solutions with consistent bearing faces, controlled chamfers, and coatings such as zinc plating, hot-dip galvanizing, phosphate, black oxide, or Cr6+-free passivations. For B2B buyers, this translates into smoother assembly, predictable torque-tension behavior, and dependable field performance. Whether paired with ISO 4014/4017 bolts, studs, or threaded rod, Boen’s full nut portfolio is engineered to keep critical joints tight in demanding environments.

Benefits & Use Cases of full nut,m6 full nut,m8 full nut,full nut nut,hex full nut in nut

From heavy equipment frames to conveyor guards and switchgear enclosures, hex nuts are specified wherever robust thread engagement and serviceable joints are essential. The m6 nut is a staple for panel fabrication, light machinery, and electronics enclosures, while the m8 nut is widely used in industrial machinery, HVAC brackets, and racking systems. The nut options with hot-dip galvanized coatings are suited for outdoor steelwork and infrastructure where corrosion resistance and sustained clamp load are critical.

Key advantages include consistent thread quality for reliable run-down, flat parallel faces that improve preload accuracy, and compatible finishes for your operating environment. Handan Boen Fastener Manufacturing Co., Ltd. brings sector expertise with tight process control in cold forming, machining, and surface treatment. Buyers benefit from stable dimensional accuracy, batch traceability, and flexible packing/labeling that integrate cleanly into automated lines and vendor-managed inventory. Custom requests—such as nonstandard heights, locking features, or application-specific coatings—are supported to help engineering teams meet unique performance, safety, and compliance targets.

Cost, Maintenance & User Experience

Total cost of ownership for hex nuts hinges on three levers: assembly efficiency, in-service reliability, and lifecycle protection. Boen’s dimensional consistency and surface finishes support reliable thread start and reduced cross-threading risk, aiding rapid run-down—especially important in automated feeding or power-tool assembly. Correctly specified property classes and coatings reduce rework, retorque intervals, and premature corrosion, improving uptime and ROI across the asset’s lifespan.

Maintenance is minimal: store nuts dry and clean, match class/finish to the bolt and environment, and follow torque specifications. In corrosive or high-vibration settings, pair with appropriate washers, locking features, or thread-locking methods to maintain clamp load. B2B customers routinely highlight ease of installation, consistent torque-tension behavior, and reliable supply schedules as major benefits when sourcing from Handan Boen Fastener Manufacturing Co., Ltd. With lot traceability and documentation available on request, procurement and quality teams gain the transparency needed for audits and risk management without adding complexity on the shop floor.

Sustainability & Market Trends in hardware

Sustainability in fasteners increasingly focuses on longer service life, safer coatings, and responsible sourcing. Market trends favor Cr6+-free passivations, trivalent chromates, and finishes that balance corrosion resistance with environmental compliance under RoHS, REACH, and ELV frameworks. In parallel, structural and renewable-energy projects are driving demand for higher-strength, corrosion-resistant hex full nut options, as well as robust documentation and traceability throughout the supply chain.

Handan Boen Fastener Manufacturing Co., Ltd. is aligned with these priorities by offering coating options that support compliance requests, bulk packaging strategies that help reduce waste, and stable manufacturing processes that promote consistent quality and fewer line stoppages. As procurement digitizes and supply chains diversify, Boen’s focus on responsive lead times, quality control, and technical support helps buyers mitigate volatility in steel and zinc pricing while meeting ESG-oriented sourcing guidelines. The result is a future-ready approach that supports both project performance and responsible procurement imperatives.

Conclusion on nut,m6 nut,m8 nut,full nut nut,hex nut from Handan Boen Fastener Manufacturing Co., Ltd.

For B2B teams seeking dependable fastener performance, a well-specified hex nut delivers the thread engagement, preload stability, and corrosion protection that critical joints demand. Whether you need an m6 nut for panel work or an m8 nut for machinery, Handan Boen Fastener Manufacturing Co., Ltd. provides quality-driven options, flexible finishes, and documentation support to streamline sourcing and deployment. Contact us: email: shaun@boenfasteners.com. Visit our website: https://www.fastenboen.com

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.