TEL:+86 15630072814

Externally Locking Rivets - High Strength Structural Blind Rivets for Truck, Steel Frame & Container Construction | YJT 8033

home >

Products >Rivets & Fastening Solutions >Structural Blind Rivets > Externally Locking Rivets - High Strength Structural Blind Rivets for Truck, Steel Frame & Container Construction | YJT 8033

Externally Locking Rivets - High Strength Structural Blind Rivets for Truck, Steel Frame & Container Construction | YJT 8033

DESCRIPTION

PRODUCT Tags

Structural Characteristics

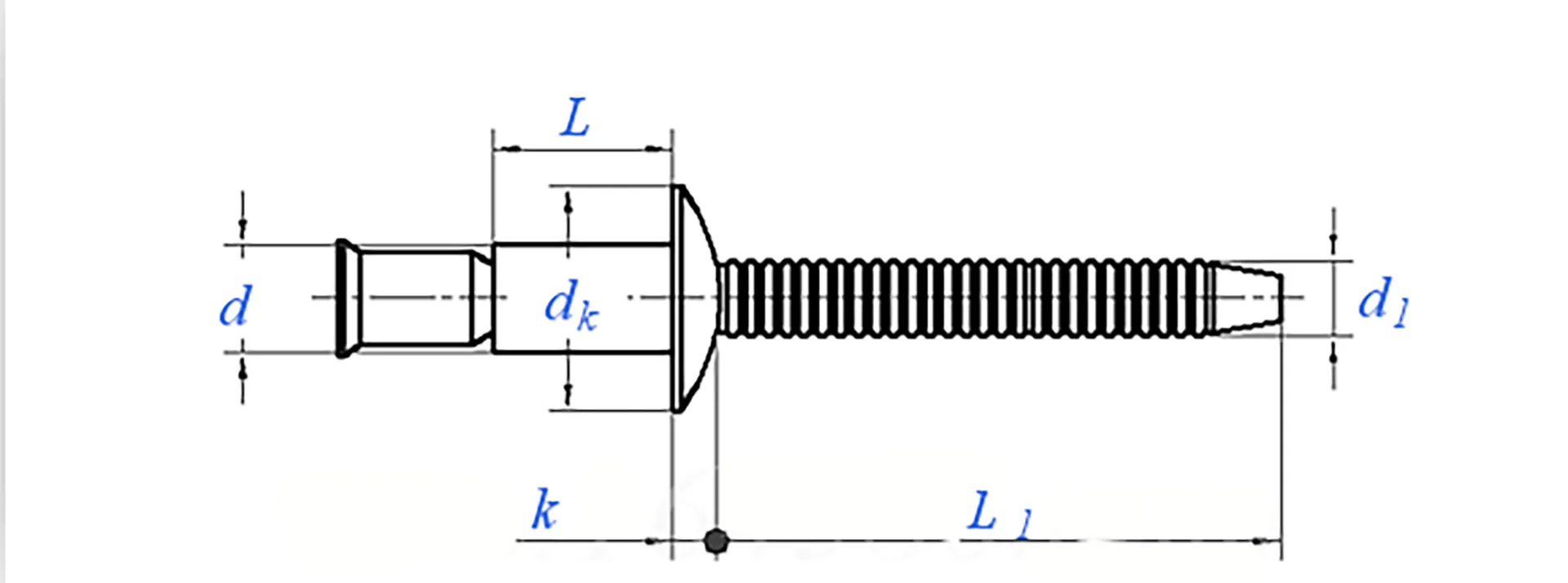

After riveting, the fractured portion of the mandrel flares out and protrudes externally from the rivet body, forming a visible locking structure (such as a cap flange or step), which facilitates inspection of connection quality. This design significantly enhances tensile strength (capable of reaching over 30 kN) and shear strength (exceeding 40 kN), making it suitable for applications requiring high-strength connections, such as steel frameworks, automobiles, and shipping containers.

Advantages of Externally Threaded (Locking Mandrel) Rivets:

· Wide grip range

· The mandrel and rivet body are securely locked, allowing for inspection at the riveted point

· High tensile and shear strength

· Sealing effect

Materials of Externally Threaded (Locking Mandrel) Rivets:

Aluminum rivet body / Aluminum mandrel

Steel rivet body / Steel mandrel

Stainless steel rivet body / Stainless steel mandrel

Types of Head Styles for Externally Threaded (Locking Mandrel) Rivets:

Dome head

Countersunk head

Large flange head

After riveting, the fractured portion of the mandrel flares out and protrudes externally from the rivet body, forming a visible locking structure (such as a cap flange or step), which facilitates inspection of connection quality. This design significantly enhances tensile strength (capable of reaching over 30 kN) and shear strength (exceeding 40 kN), making it suitable for applications requiring high-strength connections, such as steel frameworks, automobiles, and shipping containers.

Advantages of Externally Threaded (Locking Mandrel) Rivets:

· Wide grip range

· The mandrel and rivet body are securely locked, allowing for inspection at the riveted point

· High tensile and shear strength

· Sealing effect

Materials of Externally Threaded (Locking Mandrel) Rivets:

Aluminum rivet body / Aluminum mandrel

Steel rivet body / Steel mandrel

Stainless steel rivet body / Stainless steel mandrel

Types of Head Styles for Externally Threaded (Locking Mandrel) Rivets:

Dome head

Countersunk head

Large flange head

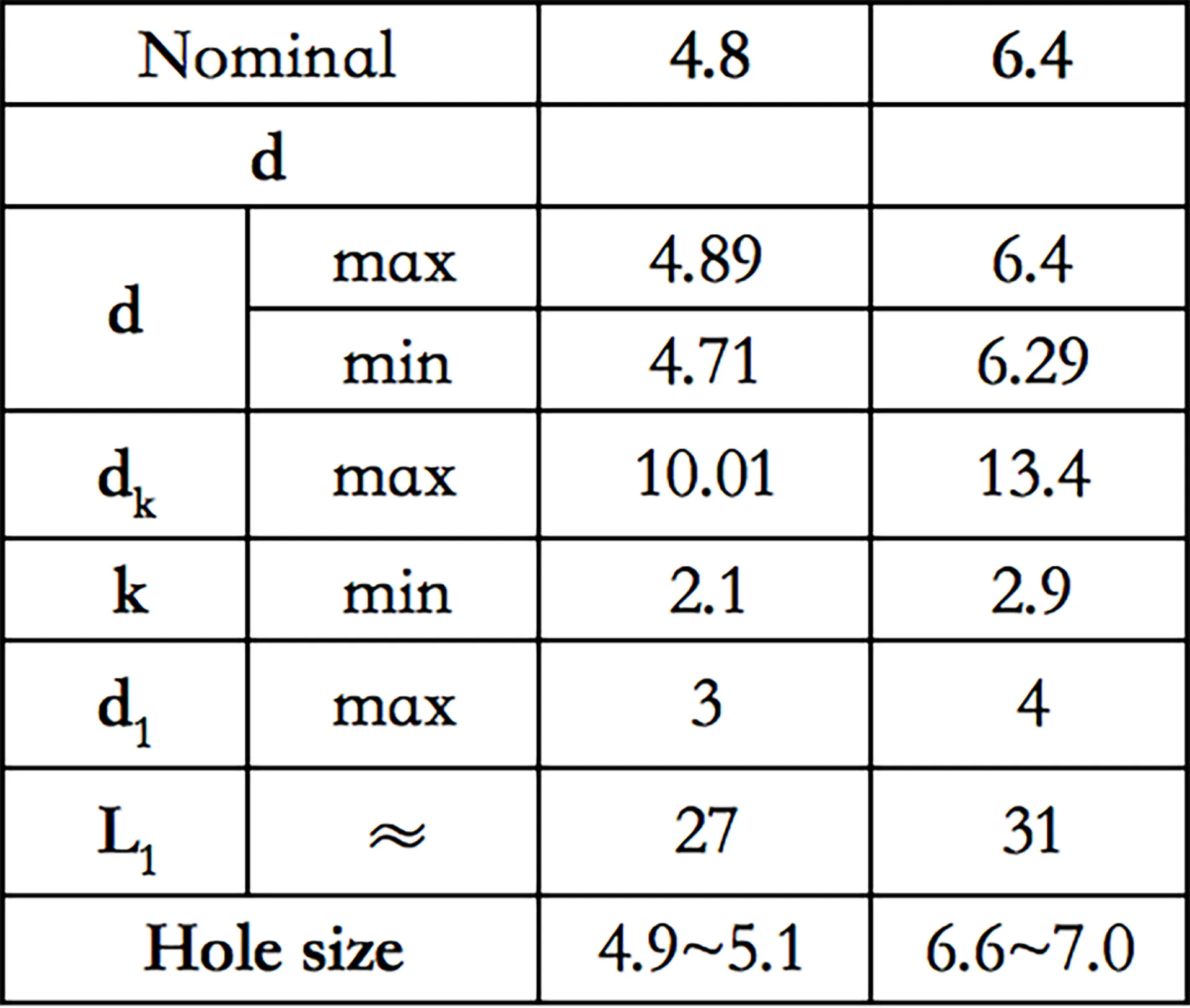

Parameter

Applications:

Aerospace Industry: Aircraft fuselage, wings and empennage, engine nacelles.

Rail Transportation: Carbody assembly, equipment installation.

High-End Commercial Vehicles and Specialized Machinery: Trucks and buses, construction machinery.