TEL:+86 15630072814

Truss Head Blind Rivets | Open End Type | 0.5-6mm Grip |GB12618.4 | ISO 14588 Certified

home >

Products >Rivets & Fastening Solutions >Blind Rivets > Truss Head Blind Rivets | Open End Type | 0.5-6mm Grip |GB12618.4 | ISO 14588 Certified

Truss Head Blind Rivets | Open End Type | 0.5-6mm Grip |GB12618.4 | ISO 14588 Certified

DESCRIPTION

PRODUCT Tags

1. What is a Blind Rivet - Introduction

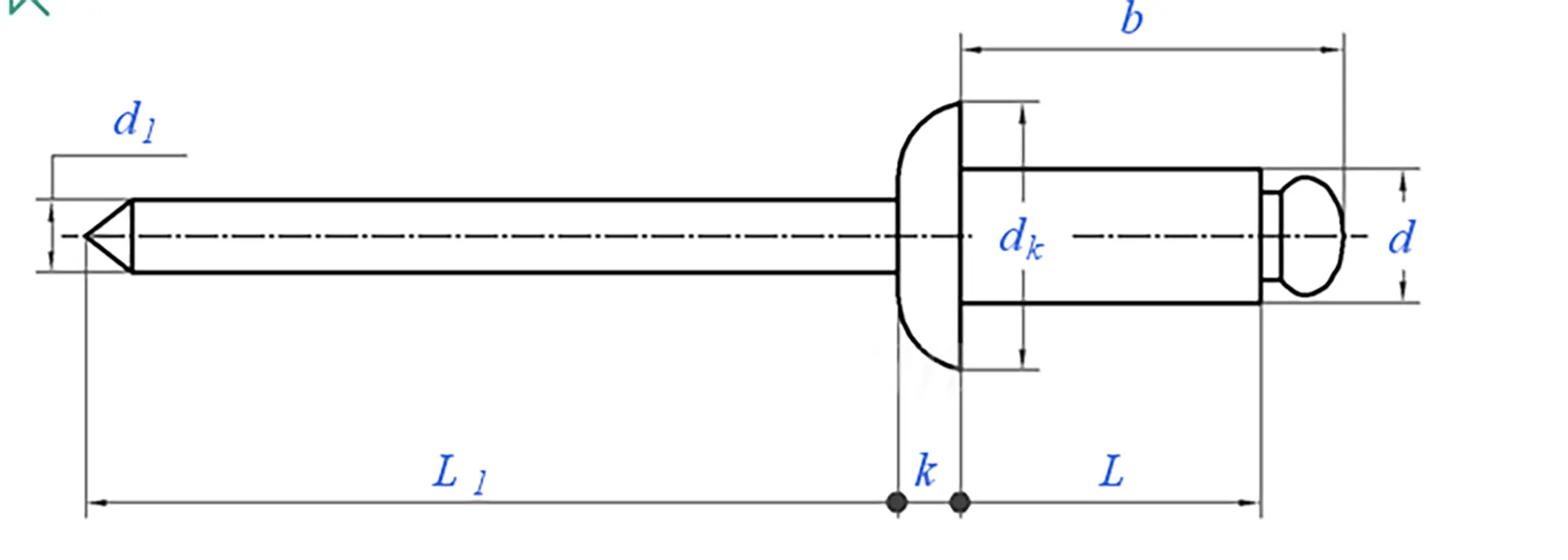

Ablind rivet consists of two parts:

a. Rivet body (also known as the sleeve head)

b. Nail core (also known as the nail or stem)

The rivet body of a blind rivet is typically manufactured using the following methods (the first being the most common):

a. Cold forging of wire

b. Sheet metal stamping

c. Tube processing

Blind rivets are particularly suitable for situations where riveting operations can only be performed from one side of the workpiece. The rivet is placed in a pre-drilled hole, and a matching riveting tool pulls the nail core. This causes the head of the nail core to be drawn into the rivet body, deforming the rivet body and causing it to expand on the back side to achieve fixation. When the head of the nail core reaches the surface of the backside material, its movement is obstructed, creating resistance. The nail core then separates at a predetermined breaking point under a set breaking force. The secure connection formed by the rivet body remains intact, with the retained portion of the nail head and the rivet body fixed together on the back side, while the broken portion of the nail core is ejected.

2. Factors to consider when selecting suitable rivets:

a. Required strength of the joint

b. Thickness of materials to be riveted

c. Material of components being riveted

d. Drilled hole size

e. Selection of head profile (typically including round head, countersunk head, large flange head, etc.)

Ablind rivet consists of two parts:

a. Rivet body (also known as the sleeve head)

b. Nail core (also known as the nail or stem)

The rivet body of a blind rivet is typically manufactured using the following methods (the first being the most common):

a. Cold forging of wire

b. Sheet metal stamping

c. Tube processing

Blind rivets are particularly suitable for situations where riveting operations can only be performed from one side of the workpiece. The rivet is placed in a pre-drilled hole, and a matching riveting tool pulls the nail core. This causes the head of the nail core to be drawn into the rivet body, deforming the rivet body and causing it to expand on the back side to achieve fixation. When the head of the nail core reaches the surface of the backside material, its movement is obstructed, creating resistance. The nail core then separates at a predetermined breaking point under a set breaking force. The secure connection formed by the rivet body remains intact, with the retained portion of the nail head and the rivet body fixed together on the back side, while the broken portion of the nail core is ejected.

2. Factors to consider when selecting suitable rivets:

a. Required strength of the joint

b. Thickness of materials to be riveted

c. Material of components being riveted

d. Drilled hole size

e. Selection of head profile (typically including round head, countersunk head, large flange head, etc.)

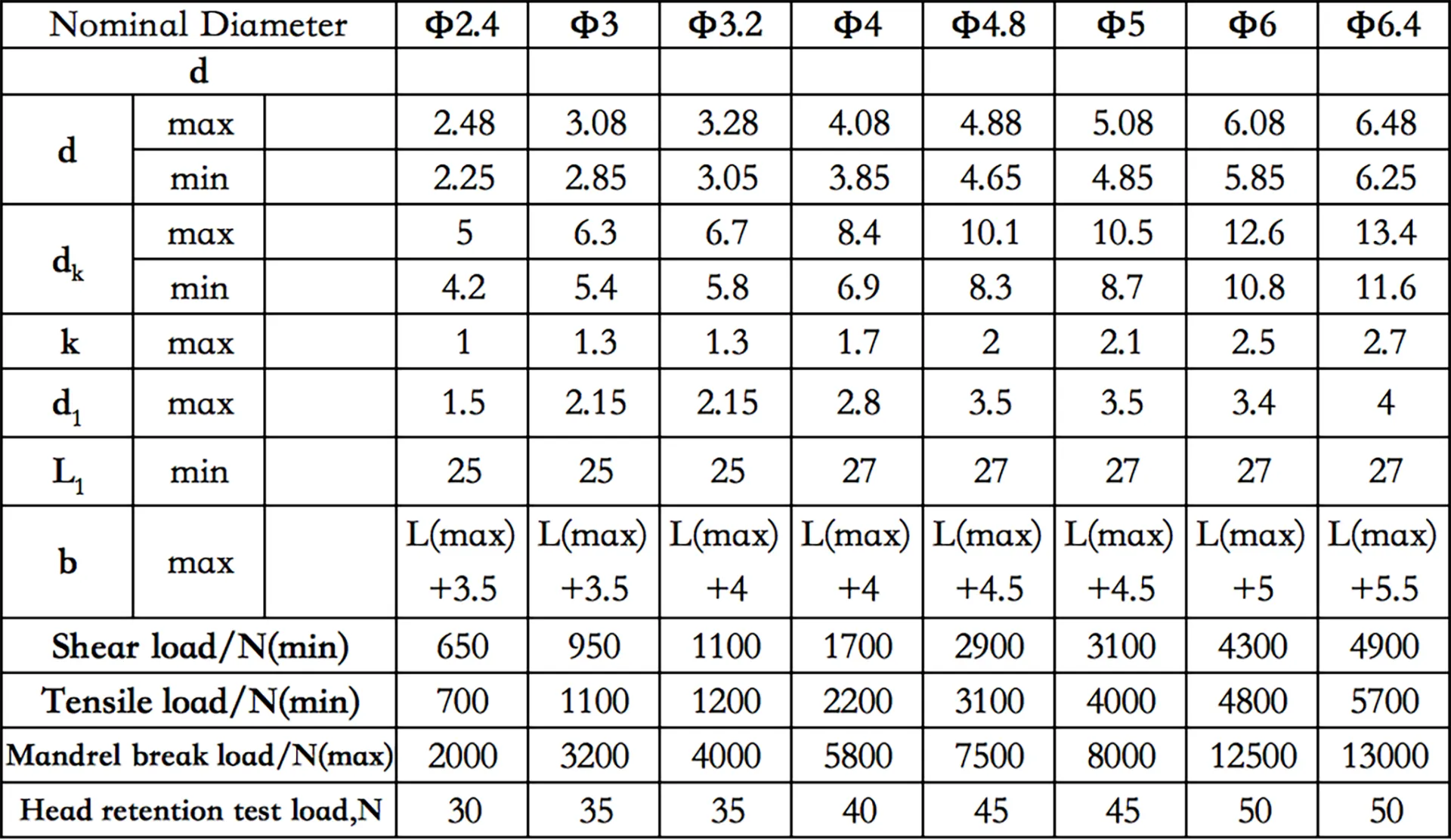

Parameter

Application Scenarios

Mechanical Equipment: Used for fastening connections in automotive, rail transit, marine vessels, and other machinery.

Construction Field: Applied for rapid fixing of doors, windows, curtain walls, and similar structural components.

Daily Use Products: Commonly employed in furniture assembly and household appliance manufacturing.