TEL:+86 15630072814

Knurled Countersunk Rivet Nut

DESCRIPTION

PRODUCT Tags

Features:

1. Countersunk Head

Smooth Flush Surface: After installation, the nut head fully embeds into the countersunk hole of the workpiece, remaining level with the material surface. This provides a streamlined appearance, eliminates snagging risks caused by protrusions, and facilitates the installation of subsequent components.

2. Knurled Grip for Anti-Rotation

Exceptional Anti-Rotation (Anti-Loosening) Capability: This is a core feature. The vertical knurling (grip pattern) on the shank of the nut bites into the wall of the mounting hole during installation, creating a powerful mechanical interlock. This effectively resists rotational forces generated when screwing in bolts or from equipment vibration, ensuring a reliable connection.

3. High Pull-Out Strength

Secure Retention: Installed using a pull-type rivet tool, the tail end of the nut expands and deforms, forming a large flange on the reverse side of the sheet. Combined with the grip of the knurling on the hole wall, it provides extremely high resistance to pull-out (extraction) forces, resulting in a solid and durable connection.

4. Blind Installation (One-Sided Installation)

Easy Installation: Installation is completed from just one side of the workpiece, requiring no access to the back. This makes it ideal for use in enclosed profiles, tubing, or cavity structures where only one side is accessible, significantly broadening its application range.

5. Low Requirement for Installation Hole

Only a Round Hole Needed: Unlike "full hex" rivet nuts which require expensive hexagonal punched holes, the knurled rivet nut only requires a simple round hole for installation, reducing processing costs and complexity.

1. Countersunk Head

Smooth Flush Surface: After installation, the nut head fully embeds into the countersunk hole of the workpiece, remaining level with the material surface. This provides a streamlined appearance, eliminates snagging risks caused by protrusions, and facilitates the installation of subsequent components.

2. Knurled Grip for Anti-Rotation

Exceptional Anti-Rotation (Anti-Loosening) Capability: This is a core feature. The vertical knurling (grip pattern) on the shank of the nut bites into the wall of the mounting hole during installation, creating a powerful mechanical interlock. This effectively resists rotational forces generated when screwing in bolts or from equipment vibration, ensuring a reliable connection.

3. High Pull-Out Strength

Secure Retention: Installed using a pull-type rivet tool, the tail end of the nut expands and deforms, forming a large flange on the reverse side of the sheet. Combined with the grip of the knurling on the hole wall, it provides extremely high resistance to pull-out (extraction) forces, resulting in a solid and durable connection.

4. Blind Installation (One-Sided Installation)

Easy Installation: Installation is completed from just one side of the workpiece, requiring no access to the back. This makes it ideal for use in enclosed profiles, tubing, or cavity structures where only one side is accessible, significantly broadening its application range.

5. Low Requirement for Installation Hole

Only a Round Hole Needed: Unlike "full hex" rivet nuts which require expensive hexagonal punched holes, the knurled rivet nut only requires a simple round hole for installation, reducing processing costs and complexity.

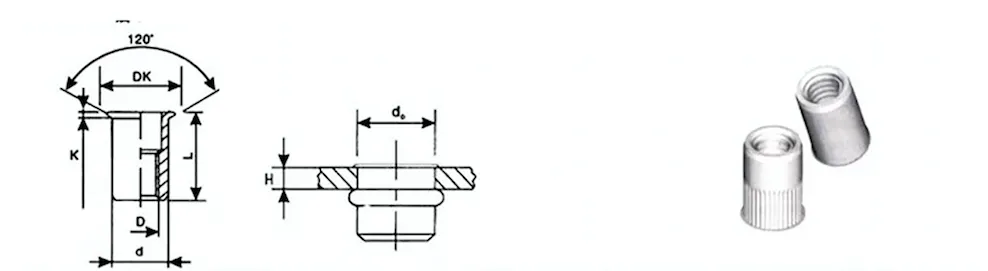

Parameter

Typical Applications:

Widely used in sheet metal fabrication, chassis and enclosures, automotive manufacturing, electronics and electrical appliances, aerospace, mechanical equipment, and other fields. Particularly suitable for applications requiring extremely high surface flatness and torque resistance.