Countersunk Hex Rivet Nuts for Sheet Metal

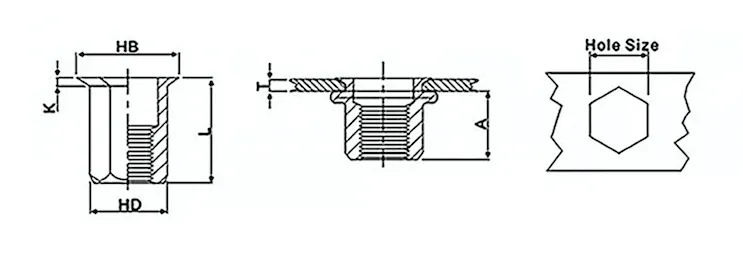

Countersunk Head

Flush Surface: After installation, the nut head sits completely below the surface of the sheet material, ensuring a smooth and unobstructed finish. This is crucial for applications requiring streamlined aesthetics, scratch prevention, or seamless integration of subsequent components.

Full Hexagonal Body

Superior Anti-Rotation Performance: This is its core advantage. Compared to round or partially hexagonal designs, the full hexagonal structure tightly interlocks with the hexagonal hole in the sheet or the counterforce generated during deformation after riveting. It withstands extremely high torque, effectively preventing rotation during bolt installation or operation.

Enhanced Load-Bearing Capacity: The hexagonal shape ensures more even stress distribution, enabling it to bear greater loads.

High Pull-Out Strength

Installed using specialized pull-through riveting tools, the tail end of the nut undergoes plastic deformation, forming a large flange on the reverse side of the sheet. This mechanically locks the nut firmly in place, providing exceptionally high resistance to pull-out forces and ensuring a reliable, durable connection.

Blind Installation

Installation can be completed from one side alone, without requiring access to the back of the workpiece. This makes it highly suitable for use in enclosed structures, profiles, tubes, or cavities where only one side is accessible, significantly expanding design possibilities.

Typical Applications:

Widely used in sheet metal fabrication, chassis and enclosures, automotive manufacturing, electronics and electrical appliances, aerospace, mechanical equipment, and other fields. Particularly suitable for applications requiring extremely high surface flatness and torque resistance.