Internal Hex Captive Screw - Stainless Steel SS304 - For Electronics Enclosure

Internal Hex Captive Screw - Stainless Steel SS304 - For Electronics Enclosure

Working Principle

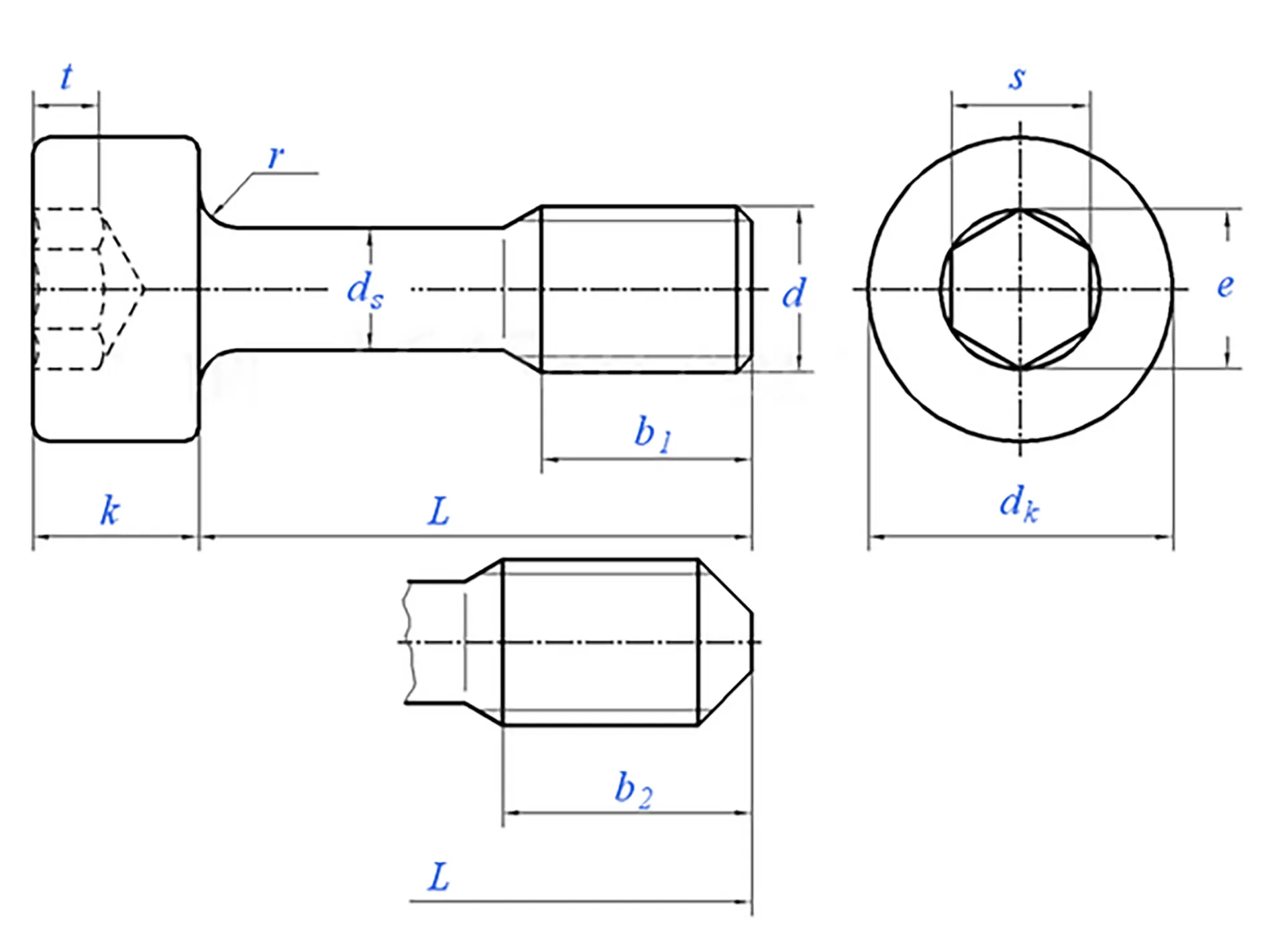

The unique operating mechanism of the Pan Head Internal Hex Captive Screw is primarily attributed to its ingenious structural design. The screw features a cylindrical head with an internal hex socket, allowing for easy tightening or loosening using a hex key. Its main structure consists of a front threaded section and a reduced shank diameter section behind it. During tightening, the threaded section engages securely with the connecting part, providing the primary clamping force. The reduced shank section plays the critical locking role. As its diameter is smaller than the threaded section, even if the screw loosens slightly under external forces, the reduced shank remains firmly within the hole of the connecting part, effectively preventing the screw from falling out completely. This design not only enhances the screw's resistance to vibration and shock but also significantly improves the reliability and safety of the connection. It is particularly suited for applications requiring high stability and security, such as mechanical equipment, electronic devices, and automotive manufacturing.

Application Scenarios

In the Field of Mechanical Equipment

In automotive manufacturing, these screws are commonly used in critical components such as the body, chassis, transmission, and engine. Their self-locking feature ensures stability even under complex operating conditions.

Construction and Installation

In building construction, captive screws are often employed to secure doors, windows, ceilings, and other parts requiring long-term stability. Additionally, they are widely used in both interior and exterior installation projects, such as metal curtain walls and lightweight partitions.