Full Nut | High-Strength Hex, M6 & M8, Fast Shipping

Full Nut is a key solution in the hardware industry, specifically within fastener and nut. This article explores how Handan Boen Fastener Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Full Nut Overview

- Benefits & Use Cases of Full Nut in nut

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in hardware

- Conclusion on Full Nut from Handan Boen Fastener Manufacturing Co., Ltd.

Full Nut Overview

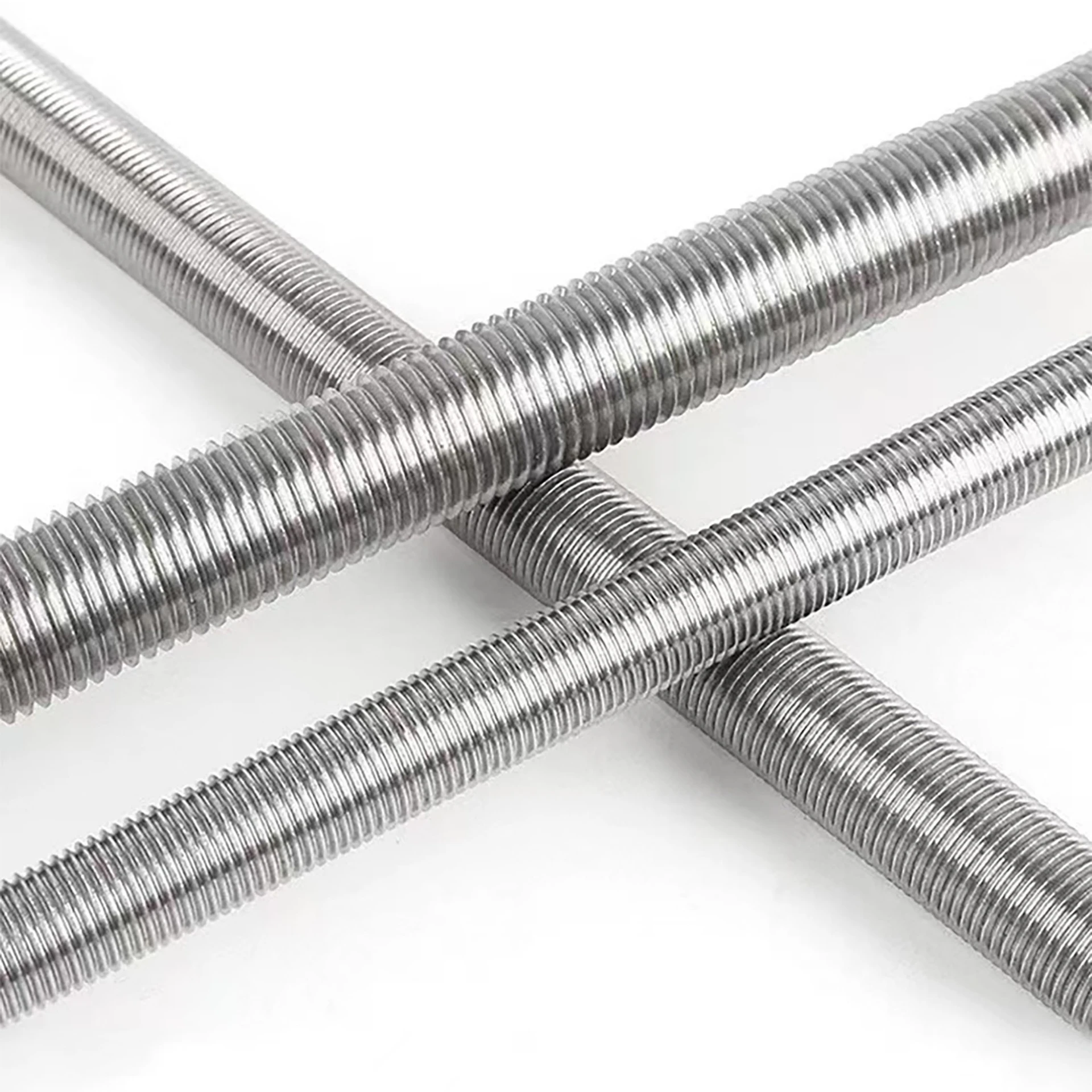

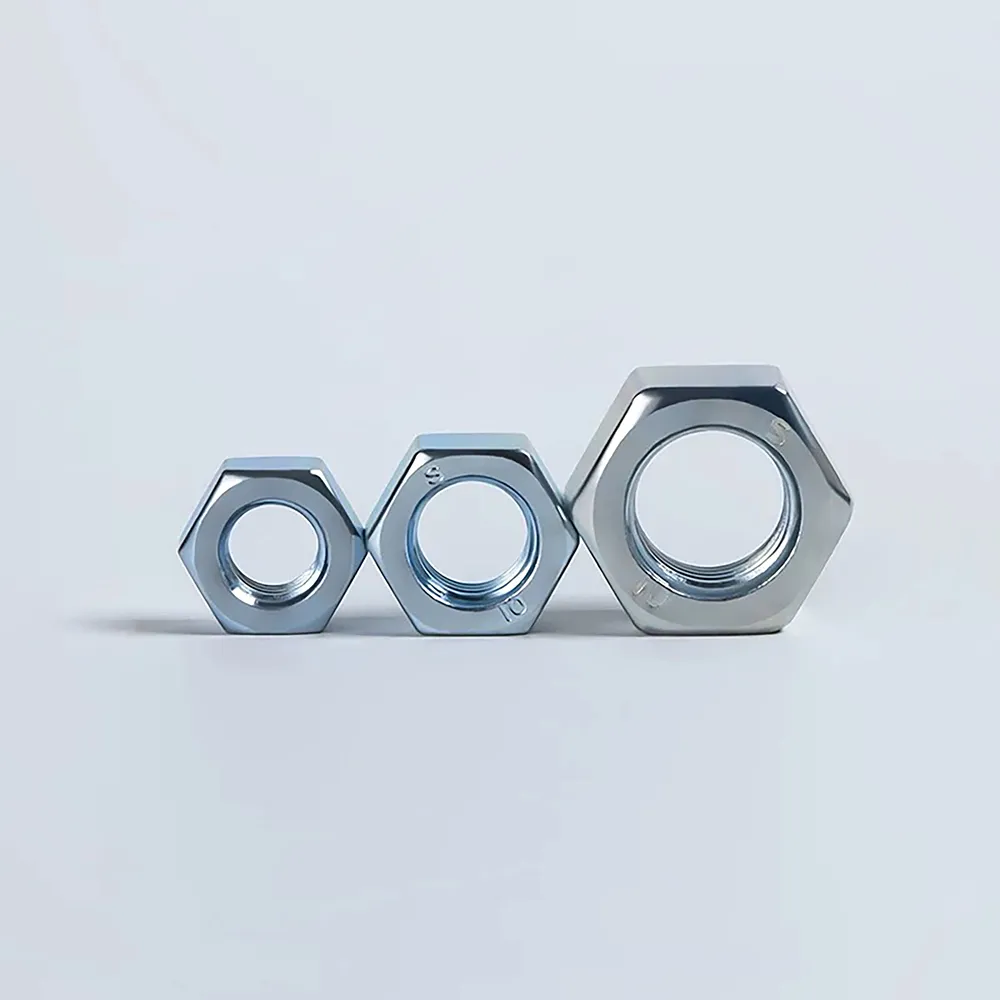

A Full Nut—often called a hex full nut—is the industry’s workhorse for high-strength assemblies across machinery, steel construction, and OEM equipment. Defined by full-height geometry and a six-sided profile for reliable wrench engagement, a Full Nut delivers the clamp load and long-term joint integrity that B2B buyers expect. Standard references include ISO 4032, DIN 934, and ASME B18.2.2, with thread tolerances typically in 6H for metric systems. Handan Boen Fastener Manufacturing Co., Ltd. supplies a wide size range from M3 up to large diameters, including popular specifications such as the M6 full nut and m8 full nut, along with UNC/UNF options on request.

- Materials and grades: carbon steel property classes 6/8/10/12; stainless options like A2 and A4 for corrosion resistance.

- Finishes: plain, zinc-plated, hot-dip galvanized, black oxide, phosphate, and modern Cr6+-free coatings for compliant performance.

- Dimensional consistency: tight flats-to-flats across a hex full nut ensure stable torque transfer and controlled preload.

As a reliable manufacturer, Handan Boen Fastener Manufacturing Co., Ltd. emphasizes stable batch quality, consistent threading, and dependable surface treatment—attributes that reduce rework and installation variance for OEMs and contractors. Whether you source a full nut nut for standard maintenance or a project-specific run, Boen aligns specifications with your drawings and packaging requirements.

Benefits & Use Cases of Full Nut in nut

In nut applications spanning structural steel, process equipment, conveyors, HVAC frames, cable trays, and panel enclosures, the Full Nut pairs with threaded bolts and studs to secure joints under vibration, thermal cycling, and shock. For light-duty assemblies and electrical enclosures, an M6 full nut is the common choice; for guardrails, racking, and general fabrication, the m8 full nut provides a versatile balance of strength and ease of installation. When higher corrosion resistance is required—such as coastal or chemical plant environments—stainless or hot-dip galvanized hex full nut variants improve time-to-maintenance.

- Application versatility: compatible with flat/spring washers, lock washers, and can be used in jam-nut arrangements for additional loosening resistance.

- Competitive advantages: predictable torque–tension behavior, consistent thread fit, and plating uniformity that supports repeatable assembly quality.

- Supply confidence: Handan Boen Fastener Manufacturing Co., Ltd. offers batch traceability, customizable packaging/labeling, and scheduling options for project rollouts and MRO stocking.

For buyers and engineers evaluating alternatives, Boen’s Full Nut portfolio allows you to standardize globally across multiple plants and contractors, reducing SKU complexity while maintaining spec compliance. Many customers also refer to this item as a “full nut nut” in sourcing lists—whichever term your team uses, Boen ensures the right fit and finish for your application.

Cost, Maintenance & User Experience

The total cost of ownership for a Full Nut centers on durability, corrosion protection, and installation efficiency. Selecting the optimal coating—zinc for indoor use, hot-dip galvanized for outdoor steelwork, or stainless for aggressive environments—extends service life and reduces unplanned maintenance. Consistent thread tolerances minimize cross-threading risks, cut assembly time, and improve first-pass yield, delivering measurable ROI for fabrication shops and field installers alike.

- Lower rework and downtime: uniform hex geometry and clean threads translate into reliable torque application and fewer line stoppages.

- Inventory efficiency: standardizing on sizes like M6 and M8 simplifies procurement and kitting, reducing carrying costs.

Feedback from long-term users in steel fabrication and MRO indicates steady repeatability of clamp load and plating appearance, even across large orders. Handan Boen Fastener Manufacturing Co., Ltd. supports user experience with clear labeling, protective packaging that limits transit damage, and responsive order handling—factors that help procurement and operations teams hit project milestones and budget targets.

Sustainability & Market Trends in hardware

Sustainability expectations in fasteners continue to rise as end-users prioritize lifecycle performance and regulatory compliance. Many buyers now specify Cr6+-free passivation, RoHS/REACH-conforming finishes, and packaging with reduced single-use plastics. In parallel, the market is shifting toward longer-life coatings and stainless solutions where the maintenance burden is high, increasing the appeal of a corrosion-resilient hex full nut for critical outdoor structures and infrastructure.

- Regulatory alignment: demand is growing for environmentally considerate coating chemistries and transparent material data.

- Operational resilience: buyers seek stable, traceable supply with clear documentation to manage risk in extended supply chains.

Handan Boen Fastener Manufacturing Co., Ltd. positions its Full Nut line with forward-thinking practices—process control for consistent coating quality, attention to wastewater handling, and collaboration on packaging optimization to reduce waste and improve cubic efficiency in shipping. This approach helps B2B decision makers meet corporate sustainability goals without compromising technical performance or delivery reliability.

Conclusion on Full Nut from Handan Boen Fastener Manufacturing Co., Ltd.

For hardware professionals, the Full Nut remains a proven, high-value fastener—reliable in preload, easy to install, and available in the right materials and finishes for virtually any environment. From M6 full nut to m8 full nut and beyond, Handan Boen Fastener Manufacturing Co., Ltd. delivers quality, consistency, and dependable lead times across your projects and MRO needs. Partner with a manufacturer that understands both engineering details and procurement realities. Contact us: email: shaun@boenfasteners.com — Visit our website: https://www.fastenboen.com

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.