TEL:+86 15630072814

Flat Head Semi-Tubular Rivets | Stainless Steel 304 | GB873 | Wholesale Price

home >

Products >Rivets & Fastening Solutions >Hollow Rivets > Flat Head Semi-Tubular Rivets | Stainless Steel 304 | GB873 | Wholesale Price

Flat Head Semi-Tubular Rivets | Stainless Steel 304 | GB873 | Wholesale Price

DESCRIPTION

PRODUCT Tags

Function and Application Scenarios

Flat head semi-tubular rivets are primarily used in applications requiring single-sided installation, such as enclosure assembly, instrument panel fixation, and lightweight bracket mounting. The riveting process only requires pressure to be applied from one side, eliminating the need for backside support, making them suitable for enclosed or hard-to-reach spaces. The semi-tubular structure allows for relatively uniform deformation during riveting, accommodating combinations of materials with varying thicknesses.

It should be noted that these rivets are generally not used in load-bearing or high-vibration environments, as their connection strength is lower than that of solid rivets or bolts.

Installation Method and Tools

Installation requires specialized riveting tools, such as manual rivet guns or pneumatic riveting machines. During operation, the rivet is first inserted into a pre-drilled hole. The tool grips the end of the rivet and applies pulling force, causing the rivet body to expand and flare outward while the head compresses firmly against the material surface. Upon completion, the tool automatically breaks off the excess portion.

It is important to ensure proper hole size compatibility: an oversized hole may result in insecure fastening, while an undersized hole can make insertion difficult. The material thickness must also fall within the rivet’s applicable range to ensure proper flaring and a reliable connection.

Differences from Other Rivet Types

Compared to solid rivets, semi-tubular rivets offer easier installation but may not be suitable for high-strength applications. In contrast to fully tubular rivets (such as blind rivets), semi-tubular rivets have a shallower hollow section, resulting in better end closure after riveting and superior moisture resistance or sealing performance. The flat head design also distinguishes them from countersunk or round head rivets, as the low-profile exposed head minimizes snagging risks with other objects.

Flat head semi-tubular rivets are primarily used in applications requiring single-sided installation, such as enclosure assembly, instrument panel fixation, and lightweight bracket mounting. The riveting process only requires pressure to be applied from one side, eliminating the need for backside support, making them suitable for enclosed or hard-to-reach spaces. The semi-tubular structure allows for relatively uniform deformation during riveting, accommodating combinations of materials with varying thicknesses.

It should be noted that these rivets are generally not used in load-bearing or high-vibration environments, as their connection strength is lower than that of solid rivets or bolts.

Installation Method and Tools

Installation requires specialized riveting tools, such as manual rivet guns or pneumatic riveting machines. During operation, the rivet is first inserted into a pre-drilled hole. The tool grips the end of the rivet and applies pulling force, causing the rivet body to expand and flare outward while the head compresses firmly against the material surface. Upon completion, the tool automatically breaks off the excess portion.

It is important to ensure proper hole size compatibility: an oversized hole may result in insecure fastening, while an undersized hole can make insertion difficult. The material thickness must also fall within the rivet’s applicable range to ensure proper flaring and a reliable connection.

Differences from Other Rivet Types

Compared to solid rivets, semi-tubular rivets offer easier installation but may not be suitable for high-strength applications. In contrast to fully tubular rivets (such as blind rivets), semi-tubular rivets have a shallower hollow section, resulting in better end closure after riveting and superior moisture resistance or sealing performance. The flat head design also distinguishes them from countersunk or round head rivets, as the low-profile exposed head minimizes snagging risks with other objects.

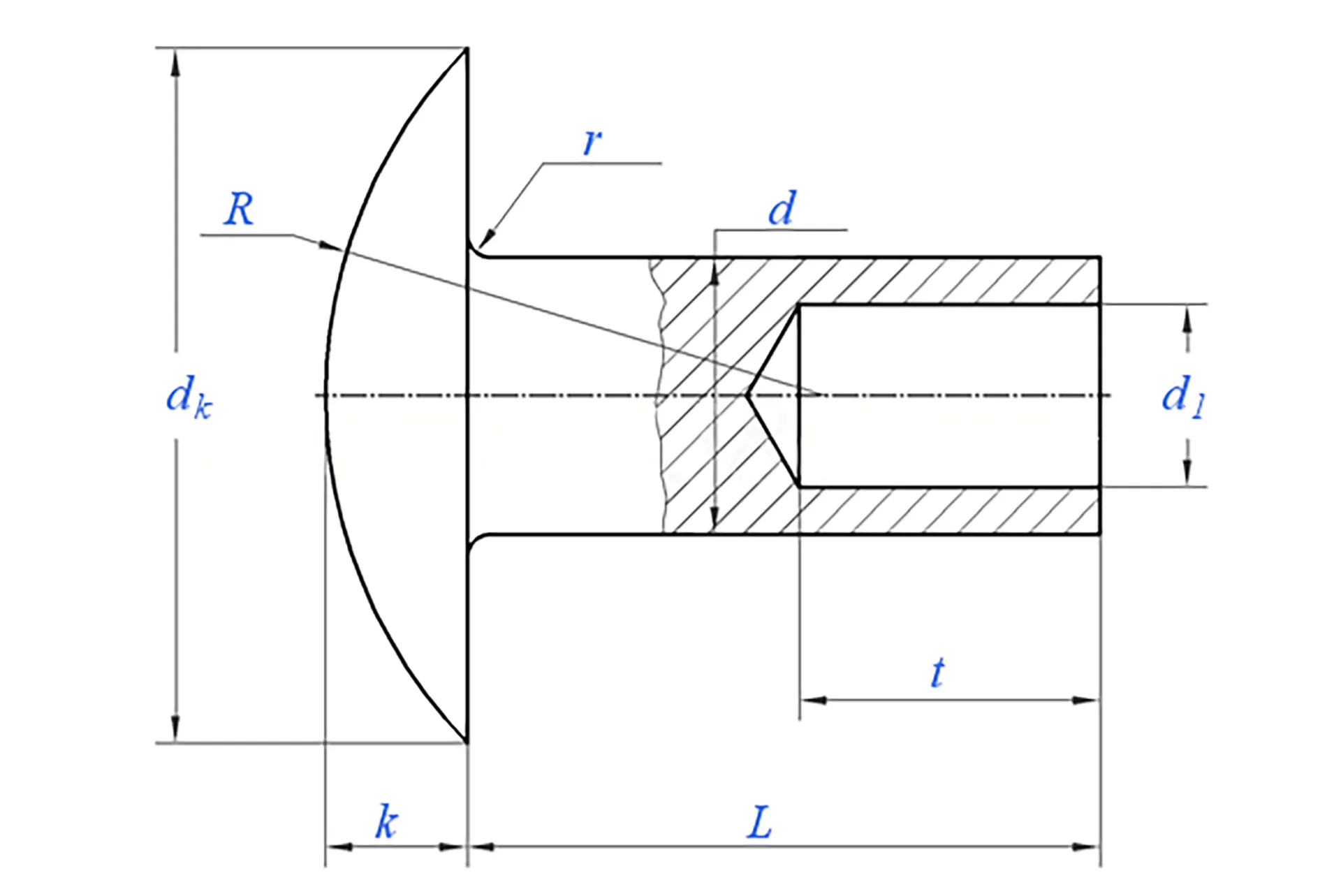

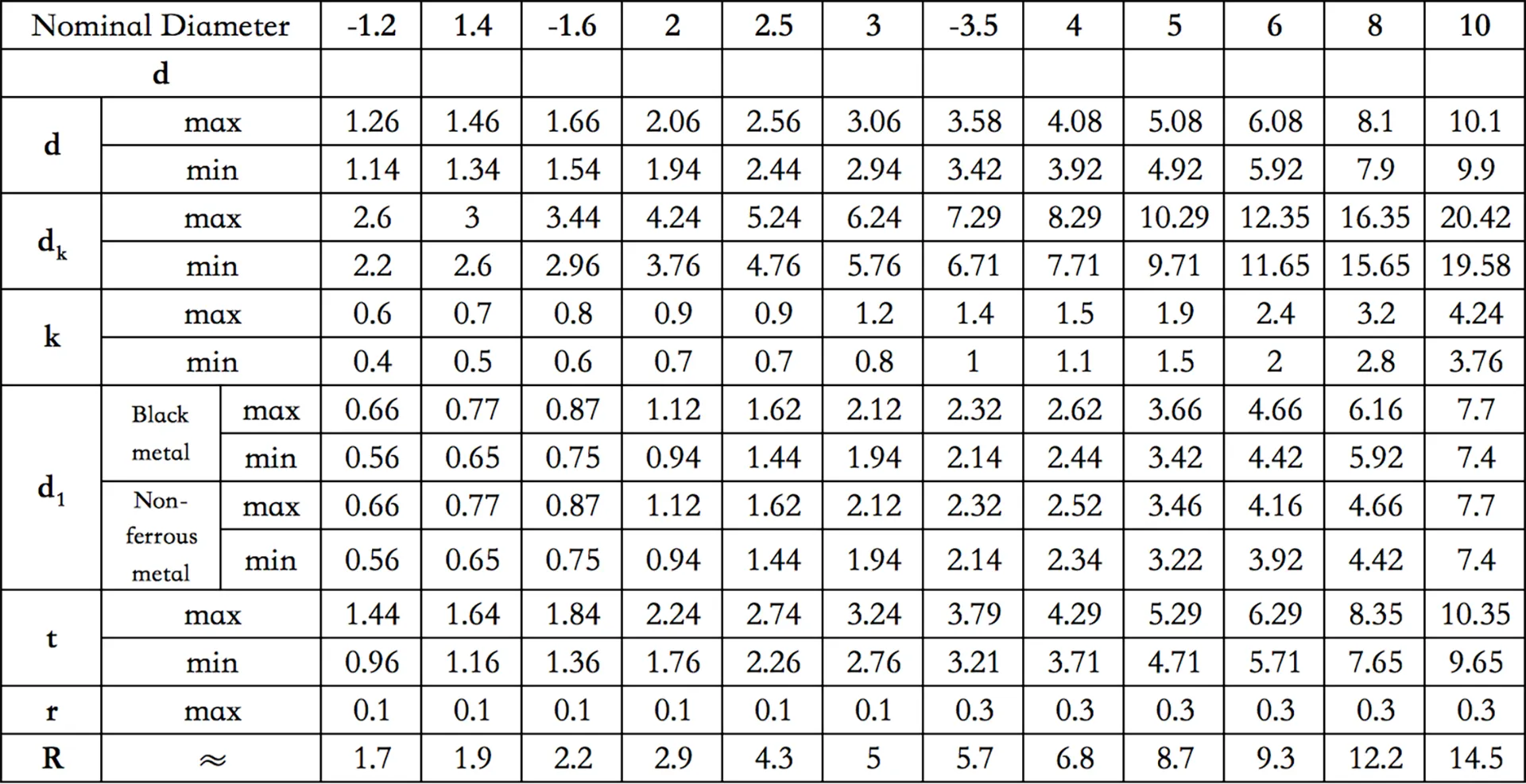

Parameter