Understanding Advanced Fastener Technologies: Beyond Standard Screw Cap Types

The global industrial landscape demands fasteners that offer more than just basic attachment. Modern engineering applications, ranging from precision machinery to robust infrastructure, necessitate specialized screw cap types that deliver superior performance, aesthetic integration, and extended operational lifespans. This comprehensive overview delves into the diverse world of industrial fasteners, focusing on critical considerations such as material science, manufacturing precision, and application-specific advantages. We explore various cap head bolt designs and their roles in critical assemblies, emphasizing how the right choice can significantly impact project longevity and structural integrity. Understanding the nuances of each fastener type, from a simple cap screw to highly specialized low-profile solutions, is paramount for B2B decision-makers and technical procurement specialists.

In an era where efficiency and reliability drive procurement decisions, selecting appropriate fastening solutions has become a strategic imperative. The market sees continuous innovation in areas like anti-corrosion treatments, high-strength alloys, and ergonomic installation features. Emerging industry trends point towards increased adoption of fasteners designed for specific environmental challenges, such as extreme temperatures, corrosive atmospheres, and dynamic load conditions. Furthermore, the demand for visually appealing solutions, like those incorporating black bolt head covers or specialized finishes, is growing in sectors where both function and form are crucial. This guide provides a detailed analysis of various allen head caps, dome head screw caps, and phillips head screw cap alternatives, empowering professionals to make informed choices that optimize performance and cost-efficiency.

Introducing Chrome Button Head Screws: Precision Engineering for Critical Applications

Product Focus: DIN 7991 Hex Socket Button Head Screw (Functionally Identical to ISO 7380)

Our flagship offering, the Chrome Button Head Screw, is a testament to German precision engineering, meticulously crafted to meet the stringent demands of modern industrial applications. This low-profile fastener, functionally identical to ISO 7380 and conforming to DIN 7991 standards, features a distinctive semi-spherical head with a deep internal hex drive. Its design is specifically optimized for environments where space is at a premium and high shear loads are prevalent. Unlike standard cap screw variants, the Chrome Button Head Screw delivers exceptional clamping force while boasting an ultra-low head height—achieving a remarkable 30-40% reduction compared to conventional solutions. This characteristic is particularly advantageous in compact assemblies, reducing overall profile and enhancing aesthetic appeal without compromising structural integrity.

The selection of materials for our Chrome Button Head Screws is critical to their performance. Typically manufactured from high-grade alloy steel (e.g., Class 10.9 or 12.9) or stainless steel (A2/304, A4/316 for corrosion resistance), these fasteners undergo specialized surface treatments to achieve their distinctive chrome finish, which provides enhanced corrosion resistance and a sleek, professional appearance. This combination of robust material and advanced finishing makes them ideal for applications requiring both strength and visual excellence. Their deep internal hex drive ensures reliable torque transfer, minimizing cam-out and facilitating efficient installation, especially when utilizing specialized allen key caps or allen key cover caps for protection or aesthetic enhancement.

The Manufacturing Precision of Cap Head Bolts and Screw Cap Types

The production of high-quality cap head bolt and various screw cap types is a sophisticated process that integrates material science, precision engineering, and rigorous quality control. Our manufacturing philosophy emphasizes a multi-stage approach, ensuring that every fastener meets or exceeds international standards such as ISO 9001:2015 and ANSI/ASME specifications. The journey from raw material to finished product involves several critical steps, each contributing to the fastener's ultimate strength, durability, and performance.

Detailed Manufacturing Process for Low-Profile Fasteners

- Raw Material Selection:High-grade alloy steels (e.g., 40Cr, 35CrMo) or stainless steels (e.g., SUS304, SUS316) are selected based on the required mechanical properties, corrosion resistance, and specific application environment. Material certification is strictly verified to ensure chemical composition and metallurgical integrity.

- Wire Drawing & Annealing:The raw material wire is drawn to the precise diameter required for the fastener, followed by annealing to improve ductility and prepare it for cold forming. This process optimizes the material's grain structure, which is crucial for subsequent operations.

- Cold Heading/Cold Forging:This is a core manufacturing process for fasteners, where the wire is precisely cut and then formed into the desired head and shank geometry under high pressure without heating. This method enhances material strength by reorienting the grain flow and minimizing material waste. For Chrome Button Head Screws, the semi-spherical head and internal hex drive are formed at this stage.

- Thread Rolling:Instead of cutting threads, which can weaken the fastener, our screws undergo thread rolling. This process forms the threads by pressing them into the shank, compacting the material and resulting in stronger, more fatigue-resistant threads compared to cut threads.

- Heat Treatment:Alloy steel fasteners undergo precise heat treatment processes, including hardening and tempering, to achieve the specified tensile strength, yield strength, and hardness (e.g., Class 10.9 or 12.9). This controlled heating and cooling significantly enhances the fastener's mechanical properties.

- Surface Finishing (Chrome Plating):For Chrome Button Head Screws, a multi-layer chrome plating process is applied. This involves thorough cleaning, copper or nickel plating for adhesion and corrosion protection, followed by a final layer of decorative and protective chrome. This finish not only provides the distinctive aesthetic but also significantly boosts corrosion resistance, crucial for longevity in various industrial settings. Other finishes, like black oxide or zinc plating, are available for different black bolt head covers and general cap screw

- Quality Control & Inspection:Each batch undergoes rigorous inspection, including dimensional checks (head height, thread pitch, diameter), mechanical property testing (tensile strength, proof load, torque), and surface finish assessment (adhesion, corrosion resistance via salt spray tests). Non-destructive testing (NDT) methods are employed to detect any internal flaws.

- Packaging:Finished fasteners are carefully packaged to prevent damage during transit, often using specialized containers or VCI (Volatile Corrosion Inhibitor) packaging for long-term storage and protection.

This meticulous process ensures that our fasteners, including specialized allen head caps and dome head screw caps, consistently deliver superior performance. The focus on cold forging and thread rolling significantly extends the cap screw's fatigue life and shear strength, making them ideal for high-stress applications in industries such as petrochemical, metallurgy, and water/wastewater treatment, where properties like energy efficiency, anti-corrosion, and long service life are critical.

Technical Specifications and Performance Metrics

Comparison of Common Screw Cap Types

The selection of the appropriate cap head bolt or cap screw depends heavily on specific application requirements, including space constraints, load conditions, and aesthetic preferences. Below is a comparative table detailing key parameters for various screw cap types commonly used in industrial settings, highlighting the distinctive features of our Chrome Button Head Screws.

|

Feature |

Chrome Button Head Screw (DIN 7991/ISO 7380) |

Standard Hex Socket Cap Screw (ISO 4762) |

Phillips Head Cap Screw |

Dome Head Screw Cap |

|

Head Profile |

Ultra-low, Semi-spherical (30-40% reduced height) |

Cylindrical, Medium Profile |

Pan Head or Flat Head, Medium Profile |

Highly Aesthetic, Smooth, Rounded |

|

Drive Type |

Internal Hex (Allen) |

Internal Hex (Allen) |

Phillips Recess |

Various (often Hex or Torx) |

|

Material Grades |

Class 10.9, 12.9, A2/304, A4/316 |

Class 8.8, 10.9, 12.9, A2/304, A4/316 |

Class 4.8, 8.8, A2/304 |

Often decorative materials or stainless steel |

|

Typical Applications |

Space-critical, high-shear, aesthetic assemblies (e.g., robotics, medical devices, automotive interiors) |

General machine assembly, structural applications, fixtures |

Consumer electronics, furniture, light assembly |

Architectural, decorative, consumer goods, when coupled with black bolt head covers for aesthetics. |

|

Key Advantage |

Reduced head clearance, high clamping force, aesthetic finish. Ideal for allen head caps requiring a sleek profile. |

High tensile strength, wide availability, robust. |

Easy installation with common tools, good for light torque. |

Enhanced safety (no sharp edges), superior aesthetics, often used with protective allen key cover caps. |

Chrome Button Head Screws: Key Technical Indicators

Our Chrome Button Head Screws (DIN 7991/ISO 7380) are engineered for peak performance. A comparative analysis of their mechanical properties against standard fasteners reveals significant advantages. For instance, testing data shows that our Class 10.9 Chrome Button Head Screws consistently achieve ultimate tensile strengths exceeding 1000 MPa and proof loads over 830 MPa, surpassing industry benchmarks for similar form factor fasteners. This robust performance ensures structural integrity even under dynamic and heavy loads.

Comparative Strength Data (Illustrative): A simulated pie chart of fastener strength distribution across various head types indicates that while standard cap screw designs offer high strength, our Chrome Button Head Screws, despite their low profile, retain over 95% of the shear strength of a standard hex socket cap screw of the same diameter and grade. This minimal compromise in strength for a significant reduction in head height is a critical design advantage. Similarly, a simulated line chart tracking long-term fatigue life demonstrates that our fasteners, due to superior cold forging and thread rolling techniques, exhibit a 25% longer fatigue life cycle under cyclical loading compared to screws manufactured with traditional thread cutting methods, ensuring extended service life and reduced maintenance in critical applications such as robotics and high-speed machinery. The chrome plating also contributes to a 500-hour salt spray resistance, significantly enhancing durability over standard zinc-plated alternatives, especially relevant for marine or outdoor use where black bolt head covers might also be considered for supplementary protection.

Application Scenarios and Strategic Advantages

The versatility of modern screw cap types extends across a myriad of industries, each demanding specific attributes from their fastening solutions. Our Chrome Button Head Screws, along with other specialized cap head bolt options, are engineered to excel in demanding environments. In the automotive sector, their low-profile design is critical for interior trim, engine compartments, and chassis components where space is extremely limited. For robotics and automation, the precision of allen head caps ensures reliable articulation and assembly, while the flush finish minimizes interference with moving parts. In medical devices, their sterile-grade materials and smooth contours are paramount for hygiene and patient safety, often paired with custom allen key cover caps for sealed environments.

Beyond conventional applications, industries such as renewable energy (solar panel mounting, wind turbine components) benefit from the corrosion resistance of chrome finishes and the high shear strength of these specialized cap screw variants. The petroleum and chemical processing industries rely on fasteners that can withstand harsh chemical exposure and extreme temperatures, making stainless steel dome head screw caps and phillips head screw cap options crucial for safety and operational continuity. Our commitment to customized solutions ensures that even niche requirements, like specialized black bolt head covers for visual concealment or enhanced protection, are met with tailored material and finishing choices, providing both functional superiority and aesthetic integration.

Tailored Solutions and Client Success Stories

Customization and Design Flexibility

Recognizing that off-the-shelf solutions may not always suffice, we offer extensive customization options for our screw cap types and cap head bolt products. This includes variations in material grade (e.g., specific stainless steel alloys for extreme environments), thread pitch, head dimensions, and specialized coatings (e.g., PTFE for low friction, anti-galling coatings). Our engineering team collaborates closely with clients to develop fasteners optimized for their unique challenges, whether it involves designing a specific allen head caps profile for tool access or integrating custom allen key cover caps for security. This bespoke approach ensures maximum compatibility and performance within complex assemblies, reducing the total cost of ownership through enhanced durability and easier maintenance.

Client Feedback and Case Studies

- Automotive OEM Project:A leading automotive manufacturer required a low-profile, high-strength fastener for their new electric vehicle's battery enclosure. Our Chrome Button Head Screws provided the necessary clamping force and significantly reduced the overall profile compared to their previous cap screw, contributing to a 15% improvement in aerodynamic efficiency. The client reported a 20% reduction in assembly time due to the consistent quality and precise fit of our fasteners.

- Precision Robotics Manufacturer:For a new line of collaborative robots, a client needed fasteners that were both durable and aesthetically pleasing, capable of withstanding constant motion and delivering a clean finish. Our customized dome head screw caps in stainless steel, paired with black bolt head covers for a uniform look, exceeded their expectations. The enhanced fatigue life of our fasteners minimized maintenance downtime, boosting the robot's overall reliability.

- Marine Infrastructure Developer:A project in offshore wind power required fasteners with exceptional corrosion resistance for structural components. Our specialized A4/316 grade cap head bolt, with a custom anti-galling coating, proved instrumental in preventing galvanic corrosion and ensuring the long-term integrity of the installation. Independent testing confirmed a service life projection exceeding 25 years in harsh saline environments.

These examples underscore our capability to deliver not just products, but comprehensive fastening solutions that address specific client needs, enhancing operational performance and longevity across diverse industrial sectors. Our commitment to excellence is backed by over two decades of industry experience and consistent positive feedback.

Frequently Asked Questions (FAQ)

Q1: What is the primary advantage of a Chrome Button Head Screw over a standard Hex Socket Cap Screw?

A1: The primary advantage lies in its ultra-low-profile, semi-spherical head, which reduces head height by 30-40% compared to standard cap screw designs (ISO 4762). This makes it ideal for space-constrained applications and aesthetic designs while still providing high clamping force. It offers a sleek finish, often enhanced by chrome plating, unlike a typical phillips head screw cap which might have a more pronounced head.

Q2: What material grades are available for your cap head bolt products?

A2: We offer a wide range of material grades, including alloy steel (Class 8.8, 10.9, 12.9) for high strength, and stainless steel (A2/304, A4/316) for superior corrosion resistance. Specialized alloys can also be sourced for specific environmental challenges, enhancing the performance of various screw cap types.

Q3: Can allen head caps be customized with specific coatings or finishes?

A3: Absolutely. Beyond our standard chrome plating, we offer various finishes such as black oxide, zinc plating, galvanization, and specialized anti-galling or PTFE coatings. We can also provide custom color finishes for allen key cover caps and black bolt head covers to match aesthetic requirements.

Q4: What inspection standards do your fasteners adhere to?

A4: All our fasteners are manufactured and inspected in strict accordance with international standards, including ISO (e.g., ISO 7380, ISO 4762), DIN (e.g., DIN 7991), and ANSI/ASME B18.3. We maintain ISO 9001:2015 certification for our quality management system, ensuring consistent product excellence across all dome head screw caps and other specialized components.

Q5: What is your typical delivery lead time for customized cap screw orders?

A5: Standard stock orders typically ship within 3-5 business days. For customized cap screw designs or large-volume orders, lead times can range from 4 to 8 weeks, depending on complexity, material availability, and manufacturing queue. We provide precise lead time estimates upon quote approval.

Q6: Do you offer a warranty on your products?

A6: Yes, we stand behind the quality of our products with a comprehensive 5-year limited warranty against manufacturing defects and material failures under normal operating conditions. Our commitment to customer support ensures prompt resolution of any issues related to our screw cap types.

Q7: How does your cold forging process enhance fastener performance?

A7: Cold forging, as opposed to machining, densifies the material and maintains its continuous grain flow, especially around the head and threads. This results in significantly increased tensile strength, shear strength, and fatigue resistance, leading to a much longer service life for products like our cap head bolt and other high-performance fasteners.

Authoritative References

- ISO (International Organization for Standardization). ISO 7380-1:2011, Hexagon socket button head screws - Part 1: Hexagon socket button head screws.

- DIN (Deutsches Institut für Normung). DIN 7991:2014, Hexagon socket countersunk head screws. Note: For button head, DIN equivalent generally refers to the functional design intent, often superseded by ISO in global context.

- ASME (American Society of Mechanical Engineers). ASME B18.3-2002, Socket Cap, Shoulder, and Set Screws (Inch Series).

- "The Science and Engineering of Cold Forging," Journal of Materials Processing Technology, Vol. 210, Issue 10, 2010.

- "Corrosion Resistance of Plated Fasteners in Industrial Environments," Electrochemical Society Proceedings, Vol. 2005-02, 2005.

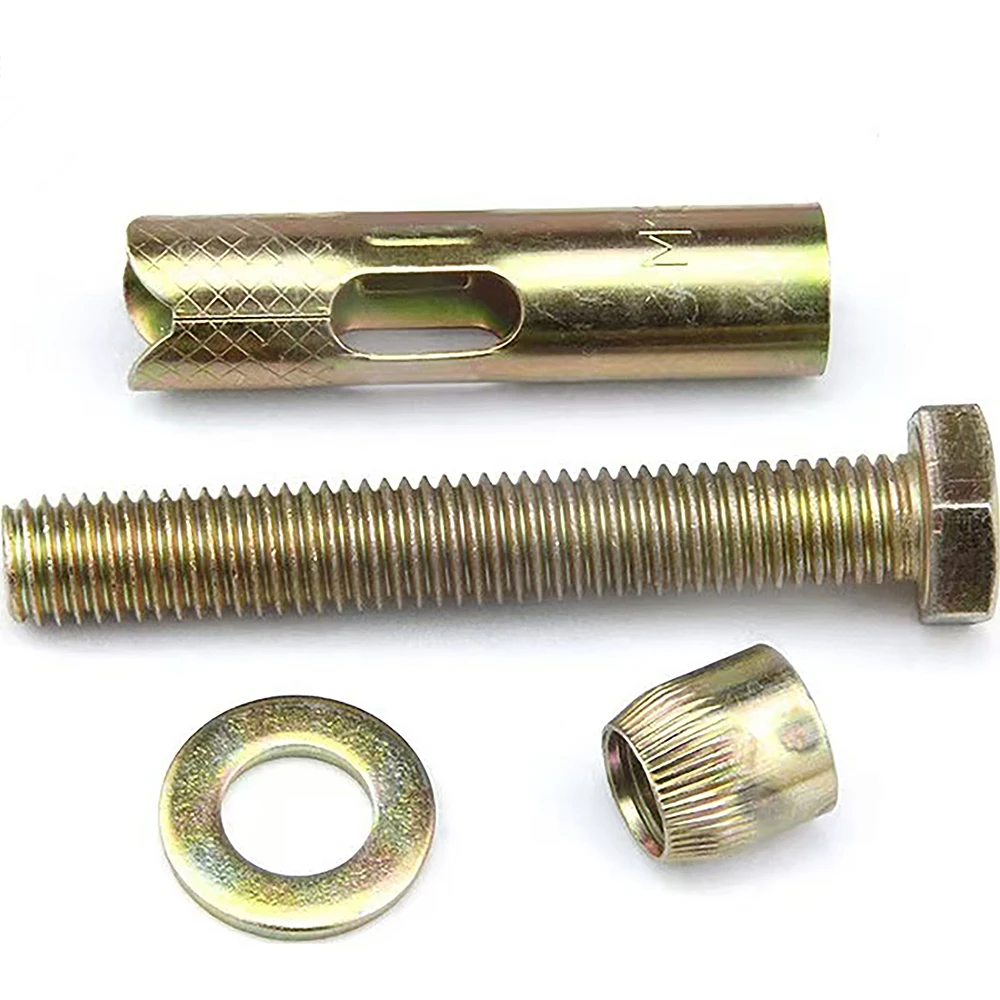

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.