TEL:+86 15630072814

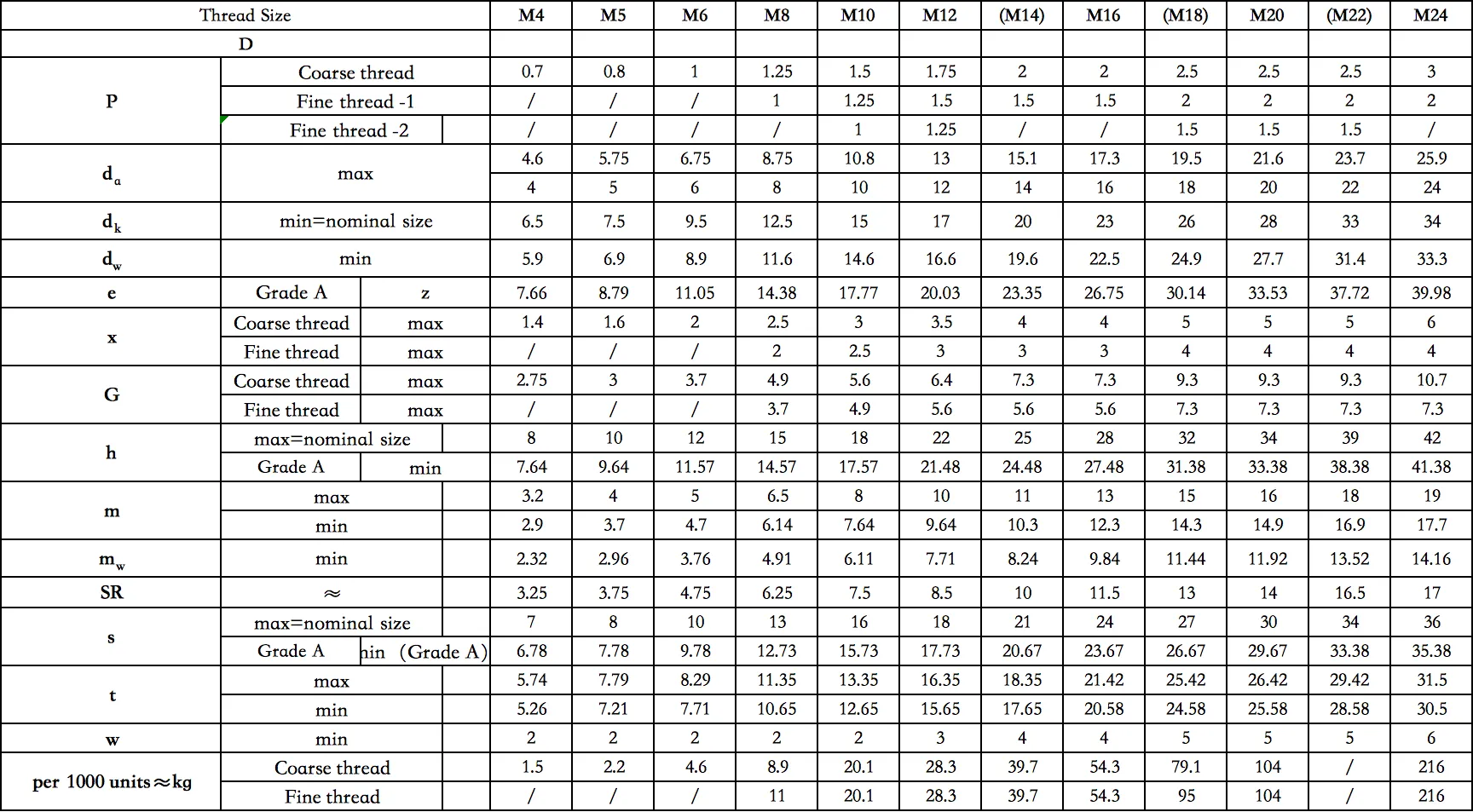

All-Metal Stainless Steel Cap Nuts | Hex Drive All-Metal Cap Nuts | High Strength for High-Pressure Use

home >

Products >Stainless Steel Fastener >Hexagon Domed Cap Nuts > All-Metal Stainless Steel Cap Nuts | Hex Drive All-Metal Cap Nuts | High Strength for High-Pressure Use

All-Metal Stainless Steel Cap Nuts | Hex Drive All-Metal Cap Nuts | High Strength for High-Pressure Use

DESCRIPTION

PRODUCT Tags

Classification by Structural Type:

(1) All-Metal Cap Nuts: Made entirely of stainless steel through integral machining, these nuts offer high strength and excellent corrosion resistance. They are suitable for high-temperature, high-pressure, or highly corrosive environments, such as chemical pipeline connections and ship equipment fastening.

(2) Nylon-Insert Cap Nuts: These nuts feature a nylon ring embedded inside the metal nut, utilizing the elasticity of nylon to provide a self-locking function that prevents loosening. They are ideal for equipment connections subject to frequent vibrations, such as automotive chassis and construction machinery.

(3) Closed-End Cap Nuts: With a fully enclosed top, these nuts effectively prevent dust, moisture, and other foreign particles from entering the bolt end. They are suitable for outdoor or humid environments, such as construction scaffolding and agricultural machinery.

(4) Open-End Cap Nuts: These nuts have an opening or groove at the top, allowing for easy inspection of whether the bolt is fully screwed in. They are applicable to connection points requiring regular inspection or adjustment, such as equipment maintenance and repair scenarios.

(1) All-Metal Cap Nuts: Made entirely of stainless steel through integral machining, these nuts offer high strength and excellent corrosion resistance. They are suitable for high-temperature, high-pressure, or highly corrosive environments, such as chemical pipeline connections and ship equipment fastening.

(2) Nylon-Insert Cap Nuts: These nuts feature a nylon ring embedded inside the metal nut, utilizing the elasticity of nylon to provide a self-locking function that prevents loosening. They are ideal for equipment connections subject to frequent vibrations, such as automotive chassis and construction machinery.

(3) Closed-End Cap Nuts: With a fully enclosed top, these nuts effectively prevent dust, moisture, and other foreign particles from entering the bolt end. They are suitable for outdoor or humid environments, such as construction scaffolding and agricultural machinery.

(4) Open-End Cap Nuts: These nuts have an opening or groove at the top, allowing for easy inspection of whether the bolt is fully screwed in. They are applicable to connection points requiring regular inspection or adjustment, such as equipment maintenance and repair scenarios.

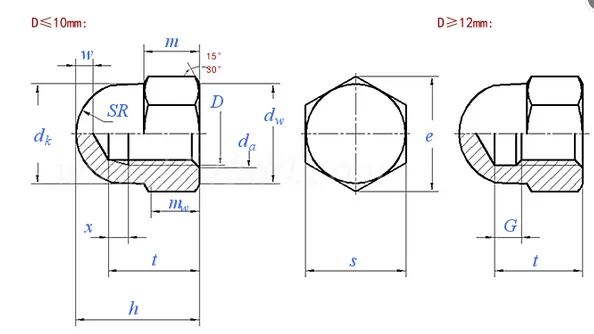

Product Parameter