din 6921 Flange Bolts 8.8 Grade – High Strength, In Stock

Din 6921 is a key solution in the manufacturing industry, specifically within Metal products industry and Manufacturing of fasteners, springs, and other metal products. This article explores how Handan Boen Fastener Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Din 6921 Overview

- Benefits & Use Cases of Din 6921 in Manufacturing of fasteners, springs, and other metal products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Din 6921 from Handan Boen Fastener Manufacturing Co., Ltd.

Din 6921 Overview

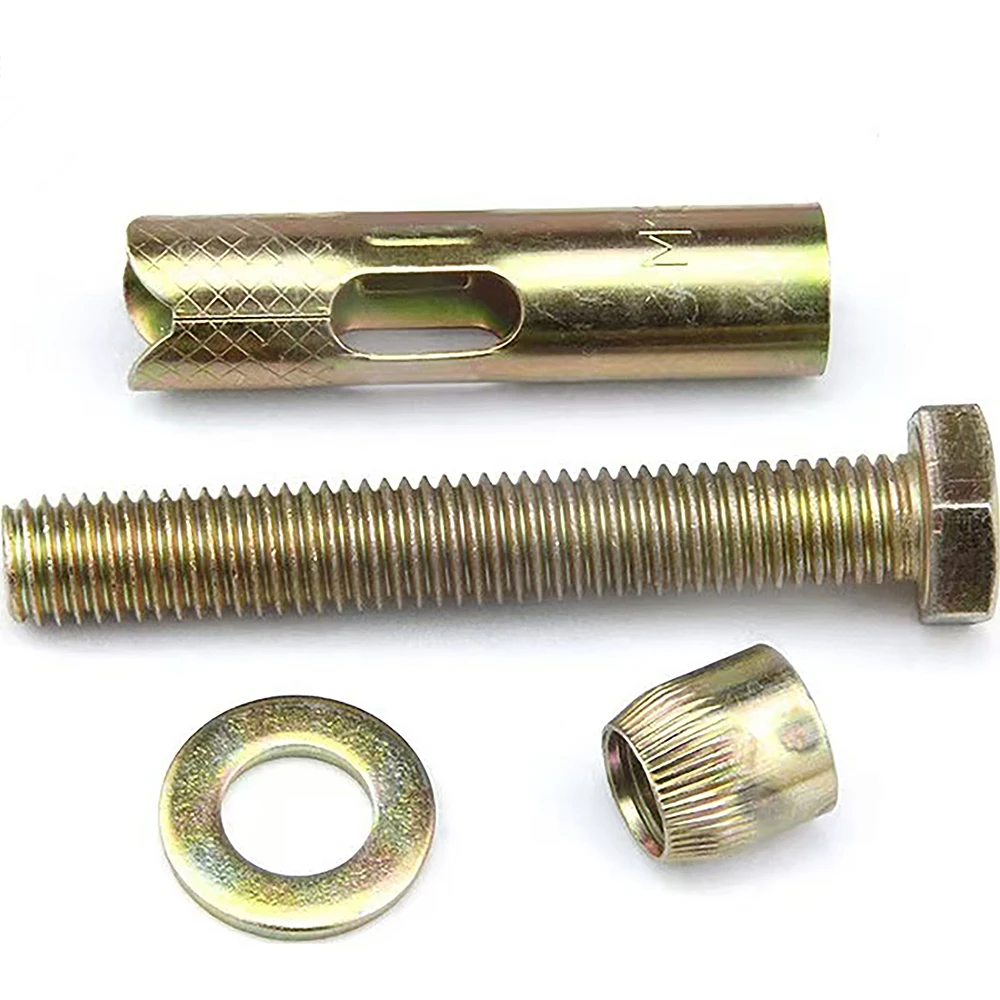

Din 6921 refers to hexagon flange bolts, a fastener that integrates a hex head with a load-spreading flange. The flange eliminates separate washers in many assemblies, accelerating production and improving clamp load stability. Typical sizes range from M5 to M24 with metric coarse and fine threads, and common property classes include Din 6921 8.8, 10.9, and 12.9 depending on the required strength. B2B buyers specify carbon steel or alloy steel with finishes such as zinc plating, hot-dip galvanizing, black oxide, or zinc-flake coatings to meet corrosion performance targets.

- Relevance: In the metal products industry, the flange head reduces component count, speeds tightening, and minimizes surface damage on sheet metal, housings, and assemblies where a washer would otherwise be needed.

- Technical notes: Mechanical properties align with ISO 898-1 for property classes; tolerances commonly follow DIN/ISO dimensional standards. Parts are supplied with a plain bearing face, with optional serrations available per project specification.

- Manufacturing partner: Handan Boen Fastener Manufacturing Co., Ltd. provides precision cold-heading and thread-rolling for consistent Dia-to-thread transitions and repeatable torque–tension performance, supporting both standard and customized Din 6921 solutions.

Benefits & Use Cases of Din 6921 in Manufacturing of fasteners, springs, and other metal products

Across automotive subframes, agricultural equipment, compressors, pumps, and general machinery, Din 6921 bolts streamline assembly and stabilize joint performance. The integrated flange spreads the load across a larger bearing surface, protecting coatings and thin materials while improving torque retention. Common in jigs, fixtures, and pressed or stamped parts, these fasteners also simplify kitting, which is valuable for high-throughput lines and contract manufacturers.

- Applications: Sheet-metal housings, gearbox covers, engine brackets, conveyor systems, and steel fabrications where washerless assembly reduces takt time and inventory.

- Competitive advantages: Faster installation, fewer SKUs, reduced risk of lost washers, improved clamp load distribution, and optional serrations for vibration-prone assemblies. Property class din 6921 8.8 is a cost-effective default; 10.9/12.9 serve high-load joints.

- Boen’s expertise: Material selection, heat treatment control, and rolled threads for enhanced fatigue strength. The company supports custom lengths, thread pitches, finishes, and packaging to align with OEM standards and on-site handling.

Cost, Maintenance & User Experience

Total cost of ownership favors Din 6921 because the flange head can eliminate washers, cut assembly steps, and prevent rework caused by misapplied hardware. For B2B decision makers, the savings show up in shorter cycle times, simplified inventory, and improved first-pass yield. Durability is driven by correct property class selection, proper surface treatment, and reliable torque–tension behavior enabled by precision cold-heading and thread-rolling.

- ROI levers: Fewer components per joint, lower labor minutes, and reduced warranty risks in vibration-prone assemblies when using serrated variants where appropriate.

- Customer feedback: Buyers in the metal products sector highlight consistent dimensions, stable supply, and predictable torque values as key reasons for choosing Handan Boen Fastener Manufacturing Co., Ltd. Repeat orders often standardize on Din 6921 8.8 for general duty and upgrade selectively to 10.9 for critical joints.

Sustainability & Market Trends in manufacturing

Sustainability in fasteners is evolving from material selection to surface technologies. Trivalent zinc systems that align with RoHS, low-VOC packaging, and efficient cold-forming reduce environmental impact while protecting performance. The market also favors platform standardization—choosing versatile fasteners like Din 6921 to minimize SKU count, packaging, and logistics emissions across product lines. In parallel, engineering teams are adopting zinc-flake coatings and mechanical plating to mitigate hydrogen embrittlement risk for high-strength classes.

- Broader trends: Lightweighting in machinery, automation-ready fasteners, and traceable supply are driving specification updates. Documentation such as material certifications and dimensional reports can be provided to support quality audits.

- Forward-thinking approach: Handan Boen Fastener Manufacturing Co., Ltd. focuses on process control, efficient raw material usage, and finish options that help buyers meet environmental and regulatory requirements without compromising joint integrity.

Conclusion on Din 6921 from Handan Boen Fastener Manufacturing Co., Ltd.

Din 6921 hex flange bolts deliver dependable clamp load, faster assembly, and fewer components—ideal for metal product manufacturers and fastener-intensive operations. With flexible options from Din 6921 8.8 to high-strength classes and a range of protective finishes, Handan Boen Fastener Manufacturing Co., Ltd. is a trusted partner for performance and value. To specify or source your next project: Contact us: email: shaun@boenfasteners.com — Visit our website: https://www.fastenboen.com — Product details: https://www.fastenboen.com/din-6921.html

- Value recap: Better torque retention, reduced SKU count, and scalable strength classes for diverse applications.

- Reputation: A reliable manufacturer supporting quality, delivery, and configurable specifications.

- Strong CTA: Contact us: email: shaun@boenfasteners.com — Visit our website: https://www.fastenboen.com

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.