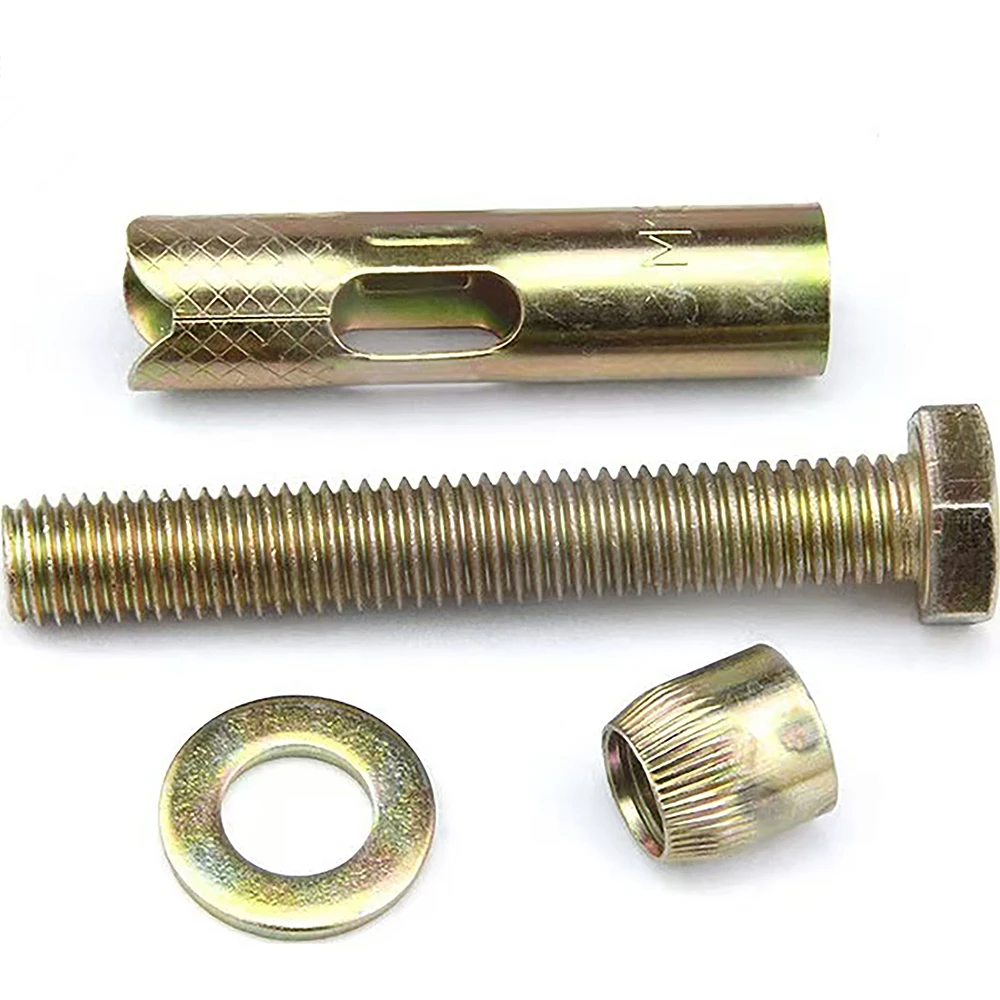

Zinc Plated Flat Washer DIN 125A, Corrosion Resistant 3/8

Zinc Plated Flat Washer: specs, real-world use, and a few things people don’t say out loud

The Zinc Plated Flat Washer looks ordinary, but it does the quiet work that keeps joints tight, finish intact, and maintenance teams happier. Originating from Hanguang Industrial Park, Yongnian District, Handan City, Hebei Province—an area that practically breathes fasteners—this washer type shows up in automotive brackets, HVAC mounts, solar frames, furniture, and plenty of MRO kits. And yes, I’ve seen engineers debate washer hardness like it’s a coffee roast. Fair enough: it matters.

What’s trending

Two steady shifts: tighter plating controls (for corrosion) and more lot-level traceability. Automotive and renewables ask for ISO 4042 compliant zinc with post-bake hydrogen embrittlement relief, plus salt-spray data on every batch. Many customers say they prefer bright zinc for cosmetics, but increasingly choose trivalent passivation for compliance and durability. To be honest, ESG checklists are now part of washer RFQs—surprisingly rigorous for such a simple part.

Core specs (quick view)

| Standards | DIN 125 / ISO 7089 (plain), ASTM F436 (hardened, optional) |

| Material | Carbon steel (Q235/C1018), medium carbon (45#) for hardened; stainless optional |

| Sizes | M3–M36 (others by request) |

| Thickness | ≈0.5–4.0 mm depending on size and series |

| Finish | Zinc plated, trivalent passivation (clear/blue/yellow), ISO 4042 |

| Plating thickness | ≈5–12 μm (real-world use may vary by spec) |

| Corrosion (NSS) | >96–240 h to red rust typical under ISO 9227 |

| Hardness | Plain: per ISO 7089; Hardened: per ASTM F436 (≈38–45 HRC) |

| Certs | ISO 9001, IATF 16949 (where applicable), RoHS/REACH |

How it’s made (short version)

- Materials: slit steel coil (chemistry checked), sometimes medium-carbon for hardened series.

- Stamping: progressive die punches OD/ID; fender type uses larger OD tooling.

- Deburr + tumble: edge quality matters; many complaints start here.

- Heat treatment (if hardened): quench & temper to spec; hardness verified.

- Surface: alkaline clean → zinc electroplate (ISO 4042) → trivalent passivation → bake for embrittlement relief (typically 2–4 h at ≈200°C).

- Testing: thickness gauge, plating thickness XRF, NSS per ISO 9227, dimensions per ISO 4759-3, hardness (HRC/HV), torque–tension sampling.

Service life? Indoors, a Zinc Plated Flat Washer with 8–12 μm plating typically sees multi-year performance; coastal outdoor use might demand stainless or thicker coatings. I guess it depends on design margins and maintenance cycles.

Where it’s used and why

- Automotive brackets, chassis add-ons, seat frames (traceable lots).

- HVAC and MEP mounts (fewer call-backs due to paint protection).

- Solar PV frames and light steel structures (spec-driven).

- Furniture and general machinery (cost-effective, consistent).

Key advantages: load distribution, paint/galv protection, consistent clamp load, and easy replacement. A Zinc Plated Flat Washer is not glamorous, but it’s the gasket of the bolted world.

Vendor snapshot (realistic view)

| Vendor type | Origin | Lead time | Customization | Certs | Notes |

|---|---|---|---|---|---|

| Factory (Handan/Yongnian) | Hebei, China | 7–20 days | OD/ID, thickness, plating | ISO 9001, IATF 16949 | Best for large volume + traceability |

| Trading company | Mixed | 10–30 days | Moderate | Varies | Convenient for multi-item bundles |

| Local distributor | Near end user | Stock/next-day | Low | Varies | Fastest for maintenance and small lots |

Customization and QC

Options include fender style (large OD), special ID tolerances, thick washers for soft substrates, and high-thickness zinc or Zn-Ni for harsh environments. Typical documentation: PPAP (auto), material certs, plating bath records, salt-spray results, and dimensional reports. Many buyers quietly ask for bag/label customization; it helps warehouse accuracy more than you’d think.

Case study (short)

A regional HVAC OEM switched to a Zinc Plated Flat Washer with 10 μm plating and post-bake. Field returns for rust staining dropped ≈60% in six months; assembly torque scatter tightened slightly due to better flatness (customer feedback via QC logs). Not flashy, just reliable.

Final thought

If your joint needs predictable clamp load and clean cosmetics at a sensible cost, a Zinc Plated Flat Washer—specified to ISO 7089/ISO 4042, validated with NSS data—remains the pragmatic choice.

Authoritative references

- ISO 7089: Plain washers — Normal series. https://www.iso.org/standard/55264.html

- ISO 4042: Fasteners — Electroplated coatings. https://www.iso.org/standard/61435.html

- ASTM F436: Hardened Steel Washers. https://www.astm.org/f0436_f0436m-21.html

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests. https://www.iso.org/standard/63543.html

- IATF 16949: Automotive QMS. https://www.iatfglobaloversight.org/

- EU RoHS & REACH guidance. https://ec.europa.eu/environment/waste/rohs_eee/index_en.htm and https://echa.europa.eu/regulations/reach

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.