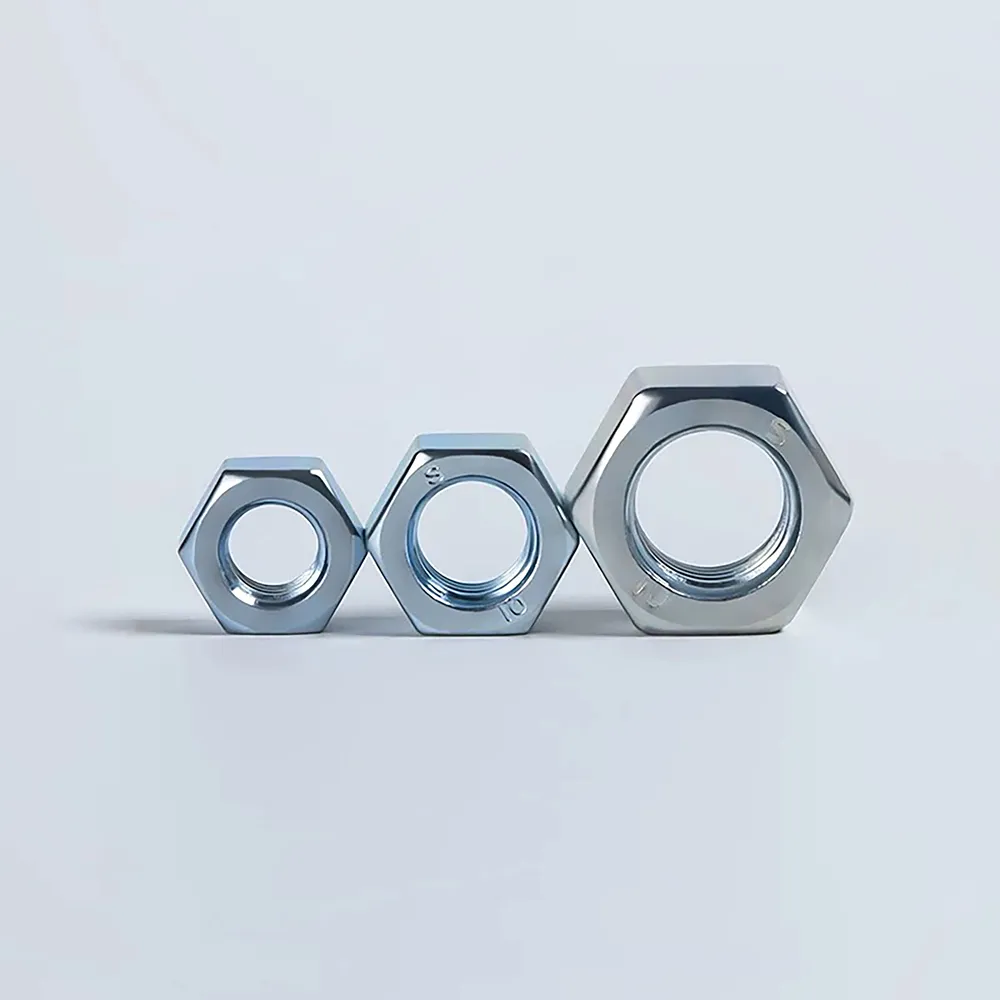

Full Nut – Durable Hex Nuts, M6/M8 Sizes, Fast Shipping

Hex Full Nut: field notes from the shop floor and the supply chain

If you buy fasteners for a living, you already know how deceptively important a simple nut can be. The [Full Nut] sits at the center of that story—humble, standard, and yet absolutely critical. I’ve watched maintenance teams baby their torque wrenches over these things, and for good reason: consistency beats drama every time.

What’s trending in the nut world (yes, really)

There’s been a quiet shift toward traceable lots, salt-spray verified coatings, and real SPC data. In fact, buyers increasingly ask for ISO 9001 certificates and PPAPs—even for basic hex nuts. Also, construction and wind projects are nudging demand for hot-dip galvanized pieces and higher property classes. It’s not flashy, but it matters.

Core specs at a glance

The Hex Full Nut from Hanguang Industrial Park, Yongnian District, Handan City, Hebei Province is built to DIN 934 (ISO 4032). Actually, that standardization is the whole point: interchangeability across global supply.

| Parameter | Typical Value | Notes |

|---|---|---|

| Standard | DIN 934 / ISO 4032 | Metric coarse/fine per ISO 261/965 |

| Size Range | M4–M48 ≈ | Real-world stock may vary by finish |

| Materials | Carbon steel (Class 8/10), SS A2/A4 | Per ISO 898-2 for carbon steel; ASTM F594 for SS |

| Threads | 6H tolerance | GO/NO-GO gauged 100% in final |

| Finishes | Zinc, HDG, black oxide, plain | Salt spray ≈ 72–600 h depending on system |

From coil to crate: process and testing

- Materials: certified wire rod (C, Mn control), SS grades A2-70/A4-70 as requested.

- Methods: cold heading, multi-die forming, CNC tapping; de-burr and ream when needed.

- Heat treatment: controlled atmosphere; hardness verified (e.g., HV 210–300 for Class 8/10).

- Coating: alkaline zinc or trivalent passivation; HDG for outdoor steelwork.

- Testing: thread ring gauge 6H; proof load per ISO 898-2; coating thickness (XRF); salt spray per ISO 9227; RoHS/REACH compliance checks.

- Service life: around 10–25 years in sheltered structural use; outdoor HDG depends on local corrosion category (C3–C5).

- Industries: construction, MRO, automotive sub-assemblies, machinery frames, solar/wind BOS.

Real test data (typical lot)

Proof-load pass rate: 99.7% over three lots (Class 8). Salt spray (zinc, trivalent): 144 h to white rust; HDG: over 480 h in our last run—your mileage varies with prep, to be honest. Thread gauge failure rate under 0.3% after tap re-sharpening cycle.

Where it actually gets used

Many customers say the [Full Nut] is the “don’t-think-about-it” fastener for steel frames, conveyor supports, ladder systems, PV racking, pipe clamps, and general MRO. In wind and outdoor signage, HDG versions are the default. In food plants, A2/A4 stainless—no surprise there.

Mini case studies

- Solar EPC in Spain: switched to HDG [Full Nut], cut redrill downtime by ~12% thanks to consistent thread tolerance.

- Machinery OEM in Poland: A2-70 lots with PPAP; reported 0 field returns in first 9 months.

Vendor comparison (my notebook version)

| Vendor | Lead Time | Certs | Traceability | Coatings | Price Index ≈ |

|---|---|---|---|---|---|

| Fastenboen (Hex Full Nut) | 15–30 days | ISO 9001, RoHS/REACH | Lot-coded, MTR on request | Zinc, HDG, black, SS | 1.00 |

| Generic Trader A | 25–45 days | Basic CoC | Limited | Zinc, plain | 0.95 |

| Factory B (Regional) | 20–35 days | ISO 9001 | Partial | Zinc, HDG | 0.98 |

Customization and paperwork

Options include brand stamping, special lubricants, nylon insert pairing, and kitting. Documentation: PPAP level 3 (when required), IMDS for automotive, and a tidy CoC pack. For projects, I’d specify a batch-specific test report for every [Full Nut] size used on site.

Bottom line

This is a no-nonsense, standards-led fastener. The trick isn’t glitz; it’s repeatability—thread quality, coating uniformity, and proof-load integrity. Get those right, and the [Full Nut] just disappears into your build, which is exactly what you want.

Authoritative references

- ISO 4032: Hexagon nuts, style 1 – Product grades A and B.

- ISO 898-2: Mechanical properties of fasteners – Nuts with specified proof load values.

- ISO 9227: Corrosion tests in artificial atmospheres – Salt spray tests.

- ASTM F594: Stainless steel nuts.

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.