Full Nut for Secure Fastening—Why Choose Our Hex Full Nut?

full nut, m6 full nut, m8 full nut, full nut nut, hex full nut is a key solution in the hardware industry, specifically within fastener and nut. This article explores how Handan Boen Fastener Manufacturing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- full nut, m6 full nut, m8 full nut, full nut nut, hex full nut Overview

- Benefits & Use Cases of full nut, m6 full nut, m8 full nut, full nut nut, hex full nut in nut

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in hardware

- Conclusion on full nut, m6 full nut, m8 full nut, full nut nut, hex full nut from Handan Boen Fastener Manufacturing Co., Ltd.

full nut, m6 full nut, m8 full nut, full nut nut, hex full nut Overview

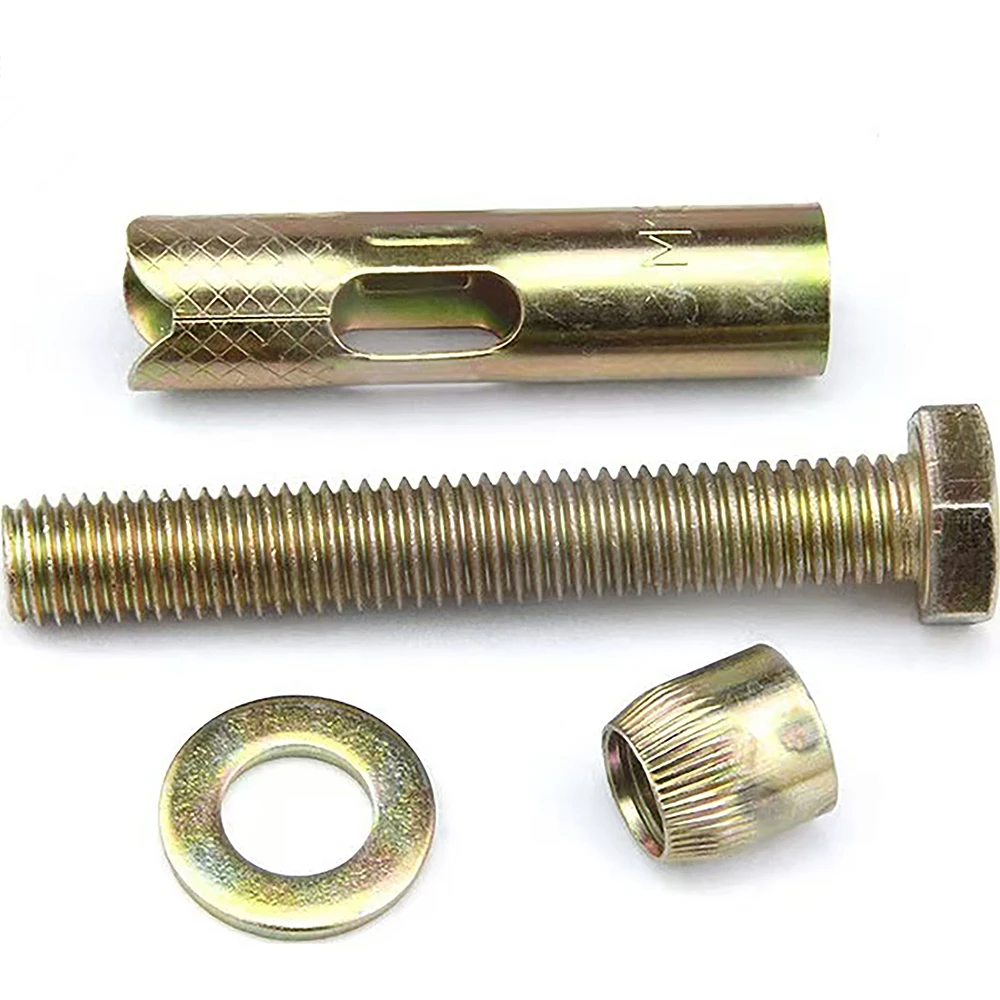

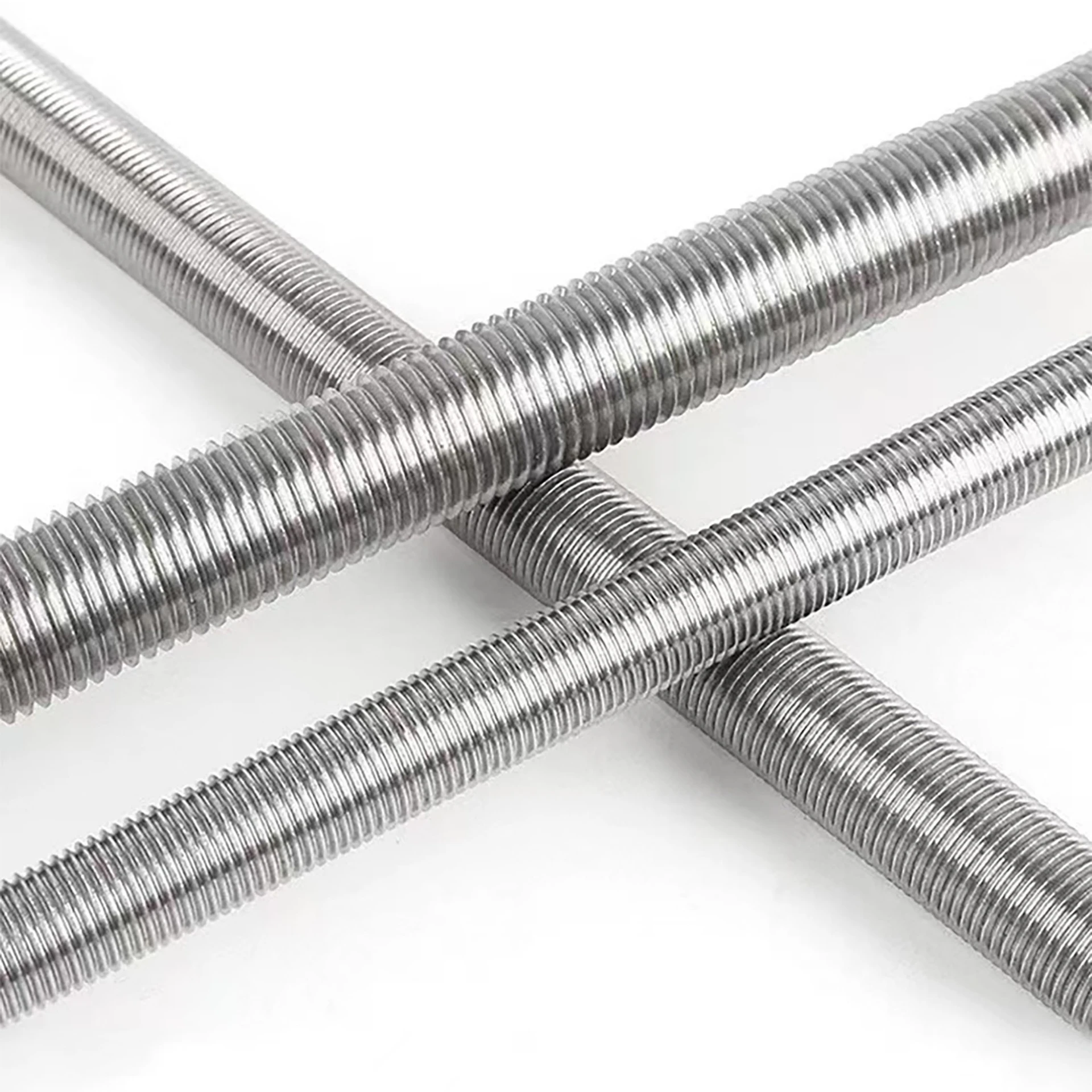

A hex full nut—often called a “full nut nut” or simply “full nut”—is the standard, full‑height hexagonal nut used to clamp assemblies with a mating bolt or stud. In hardware and fastener applications, the hex full nut is the backbone of reliable joints across machinery, steel fabrication, construction, and OEM equipment. Typical specifications include metric threads from M3 to M48 (with popular sizes such as the m6 full nut and m8 full nut), and inch threads per UNC/UNF. Compliance commonly aligns with ISO 4032/DIN 934/ASME B18.2.2, with property classes per ISO 898‑2 (e.g., 5, 8, 10, 12) and stainless options such as A2‑70/A4‑70/80.

Handan Boen Fastener Manufacturing Co., Ltd. manufactures hex full nut products using controlled cold-forming, precision tapping, and gauged threads to ensure consistent torque–tension performance. Materials range from low-carbon and alloy steel to stainless steel, with finishes including plain, black oxide, electro‑zinc, mechanical zinc, hot‑dip galvanizing (per ISO 10684), and zinc‑flake coatings for enhanced corrosion resistance. Tight dimensional tolerances, chamfered edges, and uniform thickness enable predictable load distribution, lowering the risk of loosening in dynamic environments.

Benefits & Use Cases of full nut, m6 full nut, m8 full nut, full nut nut, hex full nut in nut

Across the nut category, full nuts secure assemblies in structural frames, conveyors, pumps, HVAC mounts, cabling trays, and solar racking. The m6 full nut is widely specified for panel fastening and light machinery, while the m8 full nut is a workhorse for general engineering, fixtures, and tooling. For outdoor steelwork and infrastructure, a hot‑dip galvanized hex full nut pairs with HDG bolts to deliver long‑term corrosion protection and reliable clamping force.

Competitive advantages of Handan Boen Fastener Manufacturing Co., Ltd. include consistent thread gauging, property-class verification, and surface finishing options tailored to service environments. Precision threads reduce cross‑threading and rework, while stable coating thickness ensures nut fit (even on galvanized studs). For B2B buyers, this translates into fewer line interruptions, predictable assembly torque, and repeatable clamp loads across high-volume runs. The company’s ability to supply standard full nut nut sizes alongside customized packaging, labeling, and documentation (e.g., material certificates, PPAP upon request) streamlines vendor consolidation and supports quality audits in regulated sectors.

Cost, Maintenance & User Experience

Total cost of ownership goes beyond unit price. With full nut selections from Handan Boen Fastener Manufacturing Co., Ltd., durability and specification accuracy reduce scrap, re‑torque, and warranty exposure. Coating choices—such as zinc‑flake or HDG—extend service life outdoors, limiting maintenance cycles and minimizing shutdowns for fastener replacement. In automated assembly, clean threads and uniform nut height shorten start times and help maintain takt rate.

Feedback from fastener sector customers highlights smoother run‑in during assembly, fewer seized threads, and stable clamp loads across batches—especially for m6 full nut and m8 full nut applications in general engineering and enclosure builds. Bulk packaging with clear lot traceability supports FIFO inventory control and quality trace-back. When combined with competitive lead times and reliable logistics, the ROI shows up in fewer production stops, lower labor minutes per joint, and extended asset uptime over the fastener’s service life.

Sustainability & Market Trends in hardware

Hardware markets are aligning with sustainability goals: hexavalent-chrome‑free coatings, RoHS and REACH compliance, and increasing demand for recyclable materials. Steel full nuts are inherently recyclable, and modern surface treatments (e.g., zinc‑flake) deliver high corrosion resistance without Cr(VI). Handan Boen Fastener Manufacturing Co., Ltd. prioritizes eco‑conscious finishing, wastewater treatment in plating, and energy‑efficient production to reduce environmental impact while maintaining performance.

Market trends include stronger demand for traceability, digital certifications, and standardization under ISO 4032 and ISO 898‑2. Growth sectors—renewable energy, data centers, transportation infrastructure, and modular construction—are driving volume for hex full nut sizes, particularly m6–m16 and HDG variants for outdoor duty. Buyers are also consolidating suppliers that can balance price, quality, and compliance. By investing in process control and greener finishes, Handan Boen positions its full nut portfolio to help B2B decision makers meet both operational KPIs and ESG commitments.

Conclusion on full nut, m6 full nut, m8 full nut, full nut nut, hex full nut from Handan Boen Fastener Manufacturing Co., Ltd.

From workshop fixtures to critical outdoor structures, the hex full nut delivers dependable clamping performance. Whether you need an m6 full nut for compact assemblies or an m8 full nut for general engineering, Handan Boen Fastener Manufacturing Co., Ltd. combines standards‑compliant manufacturing, robust coatings, and reliable logistics to lower your total cost of ownership and simplify sourcing.

Contact us: email: shaun@boenfasteners.com

Visit our website: https://www.fastenboen.com

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.