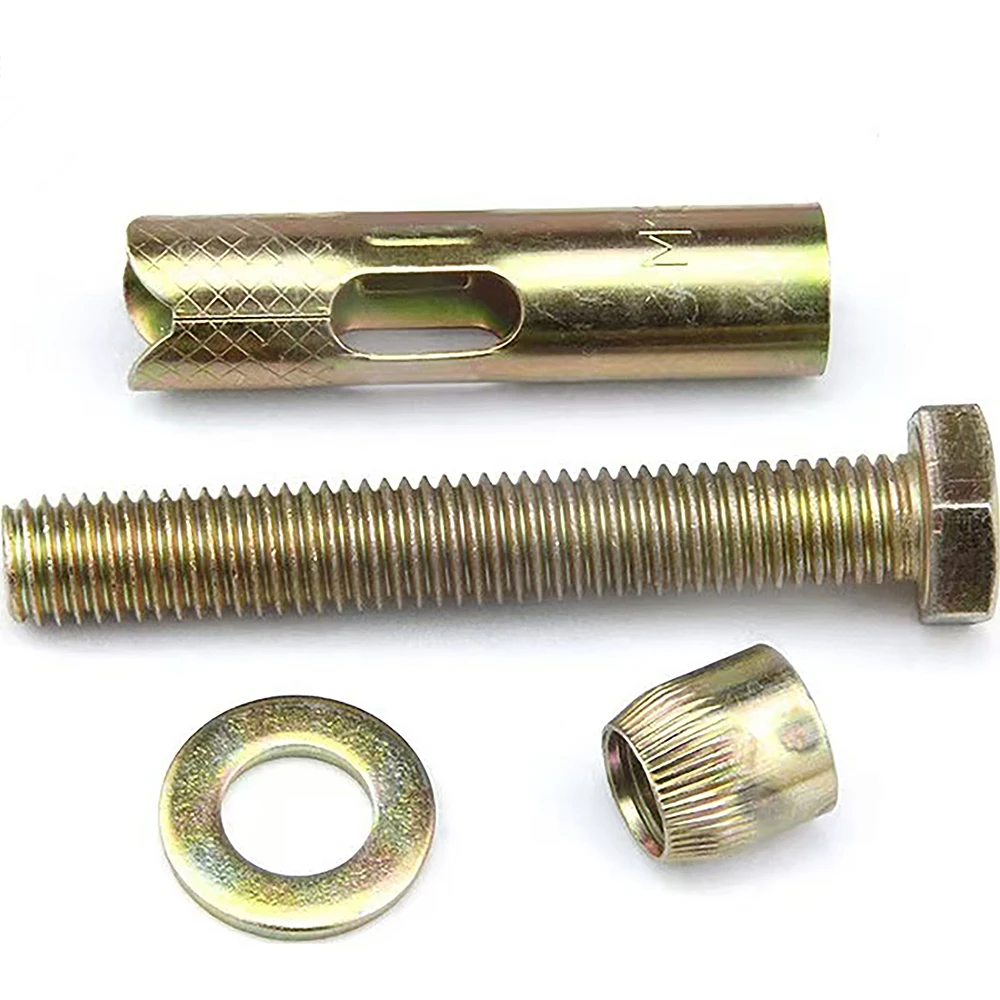

Crown Hex Nut – Precision, Corrosion‑Resistant, Bulk Supply

Field Notes on the Crown Hex Nut (aka dome/acorn cap nut)

If you work around hardware long enough, you learn which parts quietly prevent costly failures. The Crown Hex Nut is one of those. It caps the bolt, protects threads, looks tidy, and—when specced right—lasts ages. Origin here is Hanguang Industrial Park, Yongnian District, Handan City, Hebei Province, a region that practically breathes fasteners. To be honest, I’ve seen the good, the average, and the “why is this flaking already?” versions. This one leans solid.

What’s trending (and why it matters)

- Shift to stainless (A2/A4) in outdoor furniture, EV racks, and coastal fixtures; fewer warranty claims.

- Thicker domes for impact-prone assemblies in mobility devices and kids’ play equipment—small detail, big safety upgrade.

- Traceable lots with mill certs; automotive and rail buyers demand PPAP and torque-proof data, even for “simple nuts.”

Specifications that buyers actually check

Standards: DIN 1587 (domed cap nuts). Threads per ISO 965. Mechanical properties: ISO 898-2 (carbon/alloy steel) or ISO 3506-2 (stainless). Typical finishes: zinc, hot-dip galvanizing, nickel, black oxide, or organic coatings. Real-world service life ≈ 5–20 years depending on coating and environment.

| Size | Thread | Material | Finish | Grade/Property | Standard | Proof Load ≈ |

|---|---|---|---|---|---|---|

| M4–M24 (common); custom to M36 | ISO/metric, UNC/UNF | Carbon steel, A2/A4 SS, brass | Zinc, HDG, nickel, black, passivation | Class 6–10; A2-70/A4-70 | DIN 1587; ISO 898-2 / 3506-2 | Depends on class; e.g., M8 Class 8 ≈ 14–16 kN |

Process flow (how a good Crown Hex Nut is made)

- Material: certified wire rod (C1018/C1035, 40Cr), A2/A4, or brass; heat number traceability.

- Cold forming: multi-station headers shape the hex and dome; burr control matters.

- Tapping: ISO 2B/6H class; verify with GO/NO-GO gauges.

- Heat treatment: for higher classes; quench/temper to target hardness (ISO 898-2).

- Finishing: zinc (8–12 μm), HDG (≥ 40 μm), nickel, or SS passivation.

- Testing: hardness (HV), proof load (ASTM F606), salt spray (ASTM B117); thread ring checks.

- Packing: anti-corrosion paper, batch labels, QR traceability—saves headaches later.

Typical results (sample lot, zinc-plated Class 8): hardness 225–255 HV; 120 h neutral salt spray to first white rust; torque-to-failure consistent across 30 pcs (CV < 8%). Real-world use may vary.

Applications, advantages, and customization

- Applications: playgrounds, bikes/e-bikes, furniture, rail interiors, signage, architectural balustrades, HVAC covers.

- Advantages: protected threads, safer ends, cleaner look, easier cleaning, better corrosion resistance with proper finish.

- Customization: logo emboss, dome height, anti-vandal recesses, color-coated caps, kitting with bolts/washers, RoHS/REACH-compliant finishes.

Vendor snapshot (what buyers compare)

| Vendor | MOQ | Lead Time ≈ | Docs | Customization | QC/Testing |

|---|---|---|---|---|---|

| Hebei producer (Yongnian) | 5–10k pcs | 10–20 days | COC, material certs, PPAP on request | High (dome/finish/logo) | ISO-based; salt spray, F606 |

| Generic import line | 1–2k pcs | Stock/fast | Basic COC | Low | Spot checks only |

| Local fabricator | Small runs | 1–2 weeks | On request | Very high | Varies |

Mini case studies (quick hits)

Architectural railings, coastal city: Switched to A4 stainless Crown Hex Nut with polished dome; maintenance notes report no red rust at 24 months. The facilities team—usually skeptical—called it “set-and-forget.”

E‑bike assembly, EU: Zinc-nickel plated Class 8 cap nuts on axle guards. Warranty claims for thread damage dropped ≈ 35% over two seasons, according to procurement feedback.

Customer voices: “Finish is consistent box to box,” and “domes aren’t collapsing under wrenching”—comments I noted during a recent audit. Not scientific, but it tracks with the lab data.

Quick sourcing checklist

- Confirm DIN 1587 compliance and property class per ISO 898-2 or ISO 3506-2.

- Specify salt spray hours (ASTM B117) tied to your environment, not a generic number.

- Request thread gauge reports and torque-to-failure data (ASTM F606 methods).

- Ask for ISO 9001 and, if automotive, IATF 16949 from the producer—saves meetings later.

Citations

- [1] DIN 1587, Hexagon domed cap nuts, Beuth Publishing

- [2] ISO 898-2, Mechanical properties of fasteners—Nuts made of carbon steel and alloy steel

- [3] ISO 3506-2, Mechanical properties of corrosion-resistant stainless steel fasteners—Nuts

- [4] ASTM B117, Standard Practice for Operating Salt Spray (Fog) Apparatus

Who We Are: The Right Fastener Partner for Global SMEs

Handan Boen Fastener Manufacturing Co., Ltd. (Est. 2010) specializes in producing standardized industrial fasteners, including bolts, nuts, washers, and other essential components. We provide cost-effective for small and medium-sized buyers in industries such as automotive parts, agricultural machinery, and construction.